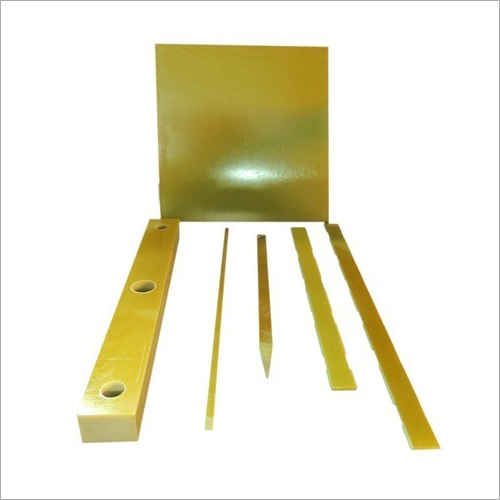

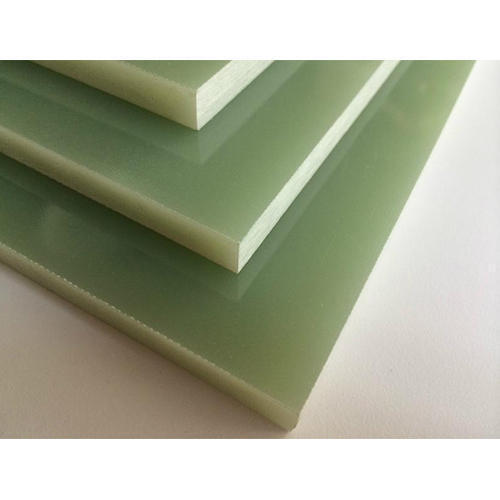

Glass Epoxy Laminated Sheets

12 INR/Meter

Product Details:

- Product Type Epoxy Sheets

- Material Glass Epoxy

- Click to view more

X

Glass Epoxy Laminated Sheets Price and Quantity

- 12 INR/Meter

- 4 Meter

Glass Epoxy Laminated Sheets Specification

- Glass Epoxy

- Epoxy Sheets

Glass Epoxy Laminated Sheets Trade Information

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

The composite material known as FR-4 sheets, often referred to as glass epoxy laminated sheets, is created by stacking glass cloth soaked with epoxy resin and curing the mixture under intense heat and pressure. Numerous industries, including electronics, automotive, aerospace, and construction, employ these sheets extensively.

Characteristics of glass epoxy laminated sheets:

1. Glass epoxy laminated sheets have high tensile strength, flexural strength, and impact resistance. They also have outstanding mechanical qualities. They can bear enormous loads and mechanical forces.

2. Excellent electrical insulators, these sheets are appropriate for use in electrical and electronic applications. They can maintain isolation between conducting components and stop electrical leakage.

3. Glass epoxy laminated sheets have good thermal stability and can endure high temperatures without suffering serious damage. They are frequently utilised in hot conditions.

4. They can be used in difficult chemical conditions because of their resistance to a variety of chemicals, including acids, bases, and solvents.

5. The low moisture absorption characteristics of these sheets ensure their dimensional stability in humid environments.

6. Dimensional stability is important for precise applications because glass epoxy laminated sheets keep their shape and dimensions across a wide temperature range.

7. FR-4 sheets have an innate ability to withstand flames and, when the heat source is removed, they can self-extinguish, improving fire safety.

8. They have excellent machinability and may be easily drilled, cut, and machined into a variety of forms and sizes, enabling the creation of unique applications and designs.

Advantages of glass epoxy laminated sheets:

1. Due to its electrical insulating qualities, mechanical robustness, and dimensional stability, glass epoxy laminated sheets are frequently utilised in the manufacture of printed circuit boards (PCBs) in the electronics industry. For many PCBs, they serve as the standard substrate material.

2. Wherever great mechanical strength and durability are required, they are employed in the manufacturing of a variety of mechanical components, including gears, bushings, and structural supports.

3. These sheets are used in the aerospace and automotive industries for parts that need to be made of robust yet lightweight materials. They help to make automobiles and aircraft lighter overall and use less fuel.

4. Glass epoxy laminated sheets are utilised as linings for tanks and vessels as well as in chemical processing equipment where chemical and high temperature resistance is essential.

5. Buildings and infrastructure projects employ them as structural components, support beams, and panels in the construction sector.

6. These sheets are a cost-effective option in the long run because of their resilience to environmental variables, which also contributes to their extended service life.

7. Glass epoxy laminated sheets can be produced to a customer's exact specifications, including thickness, size, and surface treatments.

8. By offering dependable insulation and flame resistance, they improve electrical system safety by lowering the likelihood of electrical malfunctions and fires.

FAQs of Glass Epoxy Laminated Sheets:

1. What are glass epoxy laminated sheets (also known as FR-4 sheets), and where are they most frequently used?

Ans: FR-4 sheets, also known as glass epoxy laminated sheets, are composite materials created by stacking glass cloth coated with epoxy resin and curing them under pressure and heat. Due to their outstanding electrical insulation, mechanical strength, and chemical resistance qualities, they are extensively employed in a variety of industries, including electronics (for PCBs), automotive, aerospace, construction, and chemical processing.

2. How do glass epoxy laminated sheets for electrical applications compare to other materials like metal or plastic?

Ans: Because of their high electrical insulating qualities, glass epoxy laminated sheets perform exceptionally well in electrical applications. They offer electrical isolation, shielding electrical systems from short circuits and preserving their integrity. They don't conduct electricity like metals do, and they have greater mechanical and dimensional stability than some polymers.

3. What are the benefits of employing FR-4 sheets in the manufacture of PCBs?

Ans: Because of their high electrical insulation, dimensional stability, heat resistance, and ease of machining, FR-4 sheets are the preferred substrate material for PCBs. They make it possible to produce dependable and robust PCBs for various electrical products.

4. Are glass epoxy laminated sheets safe to use and environmentally friendly?

Ans: The majority of applications are thought to be safe for glass epoxy laminated sheets, which are free of asbestos and lead. They are also eco-friendly in that they last a long time, which lessens the need for regular replacements and reduces waste.

5. Can FR-4 sheets be modified for certain uses, and what factors need to be taken into account while choosing them?

Ans: Yes, FR-4 sheets can be tailored to a project's unique needs in terms of thickness, size, and surface treatments. Considerations for choosing FR-4 sheets include the needed mechanical strength, chemical resistance, required electrical and thermal qualities, and the environment in which they will be utilised. To guarantee optimum performance in varied applications, customization options are available.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese