- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Electrical Insulating Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Laminated Fleece Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

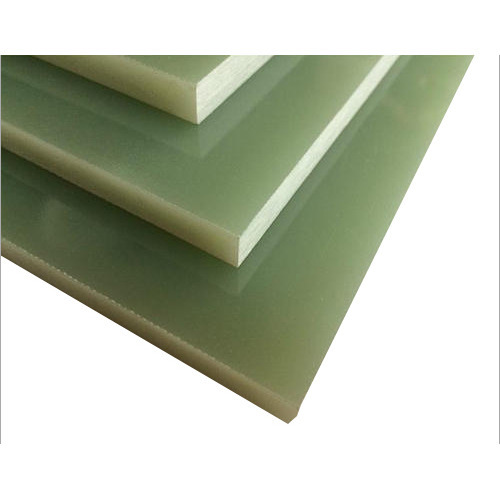

Glass Epoxy Sheet FR4

220.0 INR/piece

Product Details:

- Glass Type Woven fiberglass cloth

- Temperature -40 C to +155 C continuous (short-term up to 180 C) Celsius (oC)

- Shape Rectangular sheet / custom cut-to-size

- GSM Not applicable (solid sheet)

- Thermal Conductivity ~0.3 Watt/Meter/K (w/(m.k)

- Coating Type Uncoated

- Usage & Applications Transformers, PCB base, electrical insulation, motor slots, high-voltage equipment

- Click to view more

X

Glass Epoxy Sheet FR4 Price and Quantity

- 1 Kilograms

- 220.0 INR/piece

Glass Epoxy Sheet FR4 Specification

- -40 C to +155 C continuous (short-term up to 180 C) Celsius (oC)

- Smooth, semi-gloss finish

- Woven fiberglass cloth

- Hot-press molding from fiberglass cloth impregnated with epoxy resin

- Rectangular sheet / custom cut-to-size

- Electrical insulation, mechanical strength, thermal resistance

- Glass Epoxy Sheet (FR4 Grade)

- 1020 Millimeter (mm)

- Not applicable (solid sheet)

- Standard 1020 mm 2020 mm (custom cut available)

- Uncoated

- ~0.3 Watt/Meter/K (w/(m.k)

- Transformers, PCB base, electrical insulation, motor slots, high-voltage equipment

- Glass Epoxy (FR4 Grade)

- 2020 Millimeter (mm)

- As per thickness (0.3 mm to 50 mm) Perch

- As per size & thickness (approx. 20 50 Kg per sheet) Kilograms (kg)

- Electrical appliances, motors, transformers, PCB insulation, and high-temperature equipment

- Green / Yellow (standard colors)

- 0.3 mm 50 mm (available range) Millimeter (mm)

- 1020 2020 thickness (mm) Millimeter (mm)

- ~1.85 2.0 Gram per cubic centimeter(g/cm3)

Glass Epoxy Sheet FR4 Trade Information

- Mumbai / Bhiwandi

- Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Delivery Point (DP), Telegraphic Transfer (T/T), Cash Advance (CA)

- 4000000 Kilograms Per Month

- 2 Days

- Free samples are available

- Wooden pallets

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- All India

- CE & RoHS

Product Description

FR4 Glass Epoxy Sheet is a high-strength, flame-retardant insulating material made from woven fiberglass cloth impregnated with epoxy resin. It is widely recognized as the industry standard for electrical insulation and printed circuit boards. FR4 offers an excellent balance of mechanical strength, electrical insulation, moisture resistance, and flame resistance (UL94 V-0).

Key Features:

-

Excellent electrical insulation properties

-

Flame retardant (self-extinguishing, UL94 V-0 certified)

-

High mechanical strength and dimensional stability

-

Good resistance to moisture, chemicals, and solvents

-

Continuous operating temperature up to 130C

-

Smooth surface finish, easy to machine and fabricate

Applications:

-

Printed Circuit Boards (PCBs)

-

Transformers, motors, and switchgear insulation

-

Electrical enclosures and structural components

-

Mechanical fixtures and jigs requiring high strength & insulation

-

Aerospace, automotive, and power electronics

Available Options:

-

Color: Green / Yellow

-

Thickness: 0.2 mm 100 mm (customizable)

-

Sheet Size: Standard 1020 1220 mm / 1020 2040 mm (cut sizes available)

Exceptional Insulation and Mechanical Strength

Glass Epoxy Sheet FR4 offers robust electrical insulation and outstanding mechanical strength, making it a preferred choice for critical applications such as PCB insulation, transformers, and motors. The woven glass fabric and epoxy resin combination ensures structural rigidity and high resistance to electrical breakdown even in demanding environments.

Versatile Applications and Customization

Available in both standard and custom-cut sizes, these sheets accommodate varied industrial needs, from electrical panels to high-voltage equipment. Their adaptable thickness range and superior thermal resistance suit installations in distribution transformers, shipbuilding, and electrical appliances, providing reliable performance in multiple sectors.

FAQs of Glass Epoxy Sheet FR4:

Q: How are Glass Epoxy Sheet FR4 products typically manufactured?

A: Glass Epoxy Sheet FR4 is produced using hot-press molding, where woven fiberglass cloth is thoroughly impregnated with epoxy resin. The material is pressed and cured to achieve high density, mechanical strength, and a smooth semi-gloss finish.Q: What are the primary uses of Glass Epoxy Sheet FR4?

A: These sheets are primarily used for electrical insulation in applications such as transformers, PCB bases, motor slots, electrical panels, and high-temperature equipment thanks to their superior thermal resistance and mechanical durability.Q: When should I select custom-cut Glass Epoxy Sheet FR4?

A: Custom-cut options are ideal when your projects require specific dimensions beyond the standard 1020 mm x 2020 mm sheets. This ensures a perfect fit for specialized installations such as uniquely sized panels, transformer components, or intricate electronic assemblies.Q: Where can Glass Epoxy Sheet FR4 be applied within industry?

A: Glass Epoxy Sheet FR4 is broadly used in sectors like electrical equipment manufacturing, shipbuilding, and power distribution. Its robust characteristics make it suitable for both indoor and outdoor electrical insulation tasks.Q: What is the benefit of using FR4 grade epoxy over other materials?

A: FR4 grade epoxy provides excellent flame retardancy, high thermal stability (up to 180C short-term), and superior electrical insulation compared to many alternative materials, making it ideal for high-performance and safety-critical applications.Q: How does the sheets thermal conductivity impact its performance?

A: With a low thermal conductivity of approximately 0.3 W/m.K, these sheets efficiently prevent heat transfer, thereby enhancing electrical insulation and reliability in high-temperature environments.Q: What surface finish do Glass Epoxy Sheet FR4 sheets have?

A: Each sheet features a smooth, semi-gloss finish without additional coatings, ensuring easy handling, minimal dust retention, and straightforward installation in electrical assemblies.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese