- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Polyester Expandable Braided Sleeves

- Insulation Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Polyurethane Fiberglass Sleeve

- Fire Sleeves

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Pure Aramid (Nomex) Paper

- Electrical Insulation Papers and Laminates

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

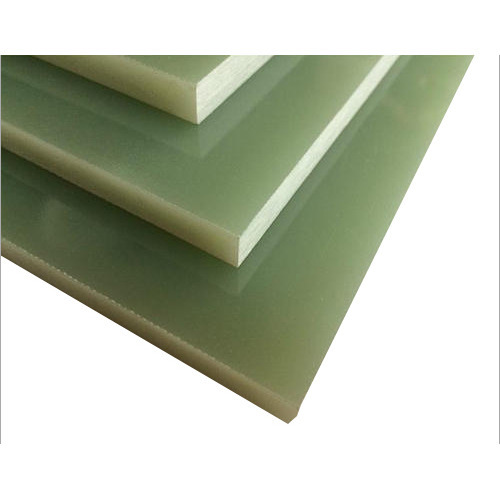

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

Fiberglass Wedges

20.0 INR/Kilograms

Product Details:

- Usage & Applications Industrial

- Usage Industrial

- Material Fiberglass

- Size Standard Sizes

- Product Type Wedges

- Color Brown

- Click to view more

X

Fiberglass Wedges Price and Quantity

- 25 Kilograms

- 20.0 INR/Kilograms

Fiberglass Wedges Specification

- Fiberglass

- Wedges

- Industrial

- Brown

- Standard Sizes

- Industrial

Fiberglass Wedges Trade Information

- 3 Days

- Asia, North America, Middle East, Africa, Central America, South America, Eastern Europe, Western Europe, Australia

- All India

Product Description

Tools or components in the shape of wedges are known as fibreglass wedges. They are utilised in a variety of applications across numerous industries because of their special qualities and adaptability.

Fibreglass wedges have the following important features:

1. Material: Layers of fibreglass fabric impregnated with a thermosetting resin, such as epoxy or polyester, are generally used to create fibreglass wedges. To make a solid, long-lasting composite, the layers are fused together and heated and compressed to cure.

2. Applications: Carpentry and construction: Fibreglass wedges are used for shimming or levelling building materials, lining up doors and windows and supporting structures.

3. Automobiles: They can be used for a variety of purposes in vehicle maintenance and production, including aligning body panels, adjusting suspension parts, or assisting with wheel alignment.

4. Marine: Fibreglass wedges can be used to strengthen connections between fibreglass components during boat construction and repair.

5. Industrial: These wedges can be used in industrial settings for precise conveyor systems, machinery alignment, and other tasks.

Fiberglass Wedges Advantages:

1. Fibreglass is naturally corrosion-resistant, thus these wedges are appropriate for use in outdoor or marine settings.

2. High Strength: Fibreglass wedges have a strong weight-to-strength ratio, which enables them to deliver support and alignment without adding a lot of weight.

3. Fibreglass has good electrical insulating qualities, which is advantageous in applications where electrical conductivity is a problem.

4. These wedges are adaptable for a wide range of applications because they come in a variety of sizes and forms.

5. Fibreglass wedges are often wedge-shaped or tapered in design, allowing for exact levelling or adjustment by inserting or removing them as required.

6. Resilience: Fibreglass wedges have a long lifespan because of its resilience and tolerance to environmental elements like moisture, chemicals, and UV radiation.

7. Maintenance: Due to their resistance to corrosion and deterioration, fibreglass wedges often require little maintenance.

In order to choose fibreglass wedges that will fulfil the needs of the project, it is important to take into account aspects like size, form, load-bearing ability, and environmental conditions. To guarantee safe and efficient applications, use these wedges in accordance with safety recommendations and best practises.

FAQs ofFiberglass Wedges:

1: What exactly are fibreglass wedges used for?

Ans - The correct definition of a fibreglass wedge is a wedge-shaped tool or component constructed of fibreglass. They are used to align doors and windows, provide structural support, and shimm or level building materials for use in construction. They are also used to align automotive parts. They can be inserted or removed as needed to make precise adjustments or levels thanks to their wedge design.

2. Why should I use fibreglass wedges over other materials?

Ans - The advantages of using fibreglass wedges include their longevity, high strength-to-weight ratios, electrical insulating qualities, and corrosion resistance. They are especially useful in outdoor, marine, or industrial settings where corrosion resistance and lifespan are crucial.

3. Can fibreglass wedges be used in electrical applications?

Ans - Fibreglass wedges do a great job at insulating electrical current. They frequently serve as insulation and isolation between components in electrical and electronic applications. They are suitable for areas where electrical conductivity must be prevented due to their dielectric qualities.

4. How can I pick the best fibreglass wedges for my project?

Ans - Consider aspects such the necessary size, shape, load-bearing capacity, and the particular environmental conditions of your project when choosing fibreglass wedges. To ensure safe and efficient use, it is imperative to select wedges that meet the requirements of your project.

5. How long do fibreglass wedges normally last and what maintenance are required?

Ans - Due to their resilience to corrosion and environmental causes, fibreglass wedges often require little maintenance. Frequently, regular cleaning is enough to remove dirt and debris. They are noted for their toughness and can have a long service life when used properly, though their lifespan can vary based on usage and environmental factors.

Fiberglass Wedge Specifications:

|

Thickness |

0.2-50mm |

|

Material |

Fiber glass |

|

Length |

50-300mm |

Engineered for Industrial Excellence

Fiberglass wedges provide superior strength and stability for various industrial applications. Their construction from high-quality fiberglass guarantees long-lasting performance and resistance to harsh environments. Brown in color and available in standard sizes, these wedges are suitable for use in manufacturing, assembly lines, and heavy-duty maintenance tasks across India.

Versatile Distribution and Supply Network

We serve as a distributor, exporter, importer, manufacturer, supplier, and trader of fiberglass wedges in India. Our extensive supply chain ensures timely delivery and impeccable service to meet the demands of small and large-scale industrial enterprises. No matter your requirements, we are equipped to support your operations with reliable products.

FAQs of Fiberglass Wedges:

Q: How are fiberglass wedges used in industrial applications?

A: Fiberglass wedges are typically used for alignment, spacing, and leveling in various industrial processes such as machinery installation, structural support, and heavy equipment assembly.Q: What are the main benefits of choosing fiberglass material for wedges?

A: Fiberglass is chosen for its high strength-to-weight ratio, resistance to corrosion, and long-term durability, making it ideal for industries where reliability is essential.Q: When should I consider using fiberglass wedges instead of alternatives like metal or wood?

A: Fiberglass wedges are preferable when you need non-conductive, corrosion-resistant, and lightweight solutions, especially in environments exposed to moisture or chemicals.Q: Where can I source these fiberglass wedges in India?

A: You can procure fiberglass wedges through authorized distributors, suppliers, or manufacturers across India. Many offer nationwide delivery and customized solutions based on your needs.Q: What is the process of ordering fiberglass wedges from your company?

A: Simply contact us with your specifications and quantity requirements. Our team will guide you through product selection and arrange delivery to your desired location.Q: How do standard sizes benefit industrial usage and applications?

A: Standard sizes ensure compatibility with a wide range of equipment and processes, allowing for faster installation and reduced downtime in industrial operations.Q: What advantages do Indian manufacturers and suppliers provide for fiberglass wedges?

A: Indian manufacturers and suppliers offer competitive pricing, quality assurance, and responsive customer support to meet diverse industrial requirements efficiently.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese