- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Acrylic Fiberglass Sleeving

- Varnished Fiberglass Sleeve F Class

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

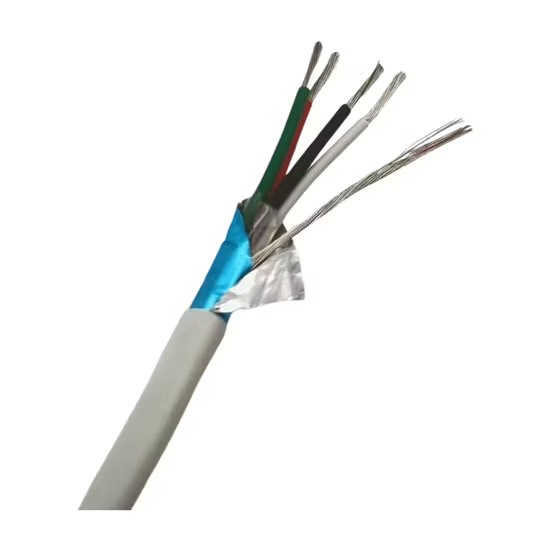

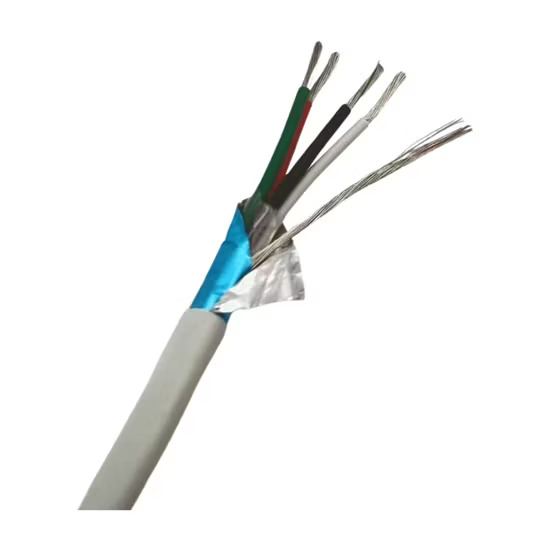

PTFE Wire

20.0 INR/Meter

Product Details:

- Connector Type Custom (Lugs / Terminals on request)

- Cable Length 100m Rolls (standard) Meter (m)

- Conductor Type Stranded / Solid Copper (customized)

- Temperature 65 C to +260 C Celsius (oC)

- No Of Core Single Core / Multi Core

- Power Rating Industrial grade, customized per requirement

- Product Type PTFE Wire / PTFE Cable

- Click to view more

X

PTFE Wire Price And Quantity

- 20.0 INR/Meter

- 1 Meter

PTFE Wire Product Specifications

- Single Phase & Multi-Phase

- High electrical conductivity & insulation resistance Ampere (amp)

- N/A (for industrial cable)

- PTFE Wire / PTFE Cable

- Copper / Silver Plated Copper / Tinned Copper

- Custom (Lugs / Terminals on request)

- 0.25 mm to 95 mm (as per design) Millimeter (mm)

- Single Core / Multi Core

- White (other colors available on request)

- Varies as per size (e.g. 5A 200A) Milliampere (mA)

- 250V / 600V / 1000V Volt (V)

- Multiple cross-sections (0.25 mm 95 mm )

- Works well for low, medium & high-frequency signals Megahertz (MHZ)

- Stranded / Solid Copper (customized)

- 65 C to +260 C Celsius (oC)

- d 100m Rolls / Custom lengths available Meter (m)

- 260 Celsius (oC)

- Copper / Silver Plated Copper / Tinned Copper

- PTFE Polymer (Fluoropolymer)

- High-Temperature, High-Performance Electrical Insulation

- Custom (Lugs / Terminals on request)

- Stable up to 100 MHz+ for signal applications Megahertz (MHZ)

- Single Core / Multi Core Flexible Wire

- Industrial grade, customized per requirement

- PTFE Polymer (Fluoropolymer)

- Motors, Transformers, Aerospace, Medical Equipment, Electronics, and Industrial Wiring

- 100m Rolls (standard) Meter (m)

- Aerospace, Automotive, Motors, Transformers, Control Panels, High-Frequency Electronics

- Standard Manufacturer Warranty

- High dielectric strength Excellent flexibility Flame retardant & non-stick surface Chemical, oil & moisture resistant High tensile strength & durability

- Excellent dielectric strength (>20 kV/mm)

PTFE Wire Trade Information

- 3 Days

Product Description

We are here to introduce best grade PTFE wire which is basically an air-field lighting equipment. It is ideal for transformers, high performance motors and rectifiers. In addition to this, the said product is also employed in oven wiring, boiler and heater. Known for properties like compensating, thermocouple, high thermal insulation etc. It is accessible in 32AWG-10AWG, rated voltage -1100 and temperature 60 degree centigrade +105 degree centigrade. We also have it in various colors such as white, blue, yellow, green, orange, red, black, brown, purple and more. This product also finds its usage in research equipment for aerospace. Provide strong construction, maximum efficiency and resistance from heat, oil, corrosion, etc.

Polytetrafluoroethylene Wire Specifications:

1. Product implementation standards: UL758; UL certification number: E252215

2. Style No: AWM1213

3. Size: 32AWG10AWG

4. Rated Voltage: 1100 V

5. Rated Temperature: - 60 degree centigrade +105 degree centigrade

6. Conductor: silver or Nickel copper

7. Insulation: PTFE teflon

8. Color: red / yellow / blue / white / black / yellow green / brown / orange / purple / green

Applications of PTFE Wire:

Polytetrafluoroethylene (PTFE) wire is a type of insulated wire that is widely used in various applications due to its unique properties. PTFE is a synthetic fluoropolymer known for its excellent electrical insulation, high temperature resistance, chemical inertness, and low friction. These characteristics make PTFE wire suitable for a wide range of applications in industries such as electronics, aerospace, automotive, and more. Here are some common applications of PTFE wire:

1. Electrical and Electronics Industry:

- Wiring and Cable Assemblies: PTFE wire is often used in the construction of high-performance electrical and electronic components, including cable assemblies, connectors, and printed circuit boards (PCBs). Its excellent electrical insulation properties are critical in preventing electrical leakage and maintaining signal integrity.

- Coil Winding: PTFE-insulated wire is used in the winding of coils for transformers, inductors, and other electrical components. Its high-temperature resistance helps in maintaining the stability of these components.

- Temperature Sensors: Polytetrafluoroethylene wire is suitable for manufacturing temperature sensors due to its ability to withstand extreme temperatures without degrading.

2. Aerospace Industry:

- Aircraft Wiring: Polytetrafluoroethylene wire is used extensively in the aerospace industry for aircraft wiring. Its resistance to high temperatures, excellent dielectric properties, and lightweight nature make it ideal for applications in aircraft systems and avionics.

3. Automotive Industry:

- Engine Compartment Wiring: PTFE wire is employed in the automotive industry, particularly in engine compartments, where it is exposed to high temperatures and chemicals. Its heat resistance and chemical inertness make it suitable for these harsh environments.

4. Medical Equipment:

- Medical Device Wiring: PTFE-insulated wire is used in medical equipment and devices, such as diagnostic instruments and surgical tools, where high precision, electrical insulation, and biocompatibility are essential.

5. Chemical Processing Industry:

- Chemical Resistant Applications: Polytetrafluoroethylene wire is used in chemical processing equipment, where resistance to a wide range of corrosive chemicals and elevated temperatures is crucial.

6. High-Frequency Applications:

- RF and Microwave Devices: PTFE-insulated wire is commonly used in radio frequency (RF) and microwave applications due to its low signal loss, high dielectric constant, and stable electrical properties at high frequencies.

7. Laboratory Equipment:

- Scientific Instrumentation: PTFE wire is used in the construction of laboratory equipment and instruments due to its chemical inertness, preventing contamination of sensitive experiments.

8. Military and Defense Applications:

- Military Electronics: Polytetrafluoroethylene wire is used in various military and defense applications, including communication systems, radar equipment, guidance systems, where reliability and performance under extreme conditions are paramount.

9. Underwater and Submersible Devices:

- Submersible Cables: PTFE-insulated wires are used in underwater applications, such as submersible sensors and equipment, due to their water-resistant properties and electrical insulation.

10. High-Performance Motors and Generators:

- Motors and Generators: PTFE-insulated wire is used in high-performance electric motors and generators, where its excellent electrical properties help in achieving optimal efficiency.

PTFE Wire FAQ:

1. What is PTFE wire?

Ans: Polytetrafluoroethylene wire is an electrical wire with a conductor (usually copper) at its core and insulation made from Polytetrafluoroethylene (PTFE). PTFE is a synthetic fluoropolymer known for its excellent electrical insulation properties, high-temperature resistance, and chemical inertness.

2. What are the key properties of PTFE wire?

Ans: PTFE wire is known for its:

- Exceptional electrical insulation.

- High-temperature resistance, typically up to 260 degree centigrade.

- Chemical inertness, resisting most corrosive chemicals.

- Low friction and nonstick surface.

- Resistance to UV radiation and weathering.

3. Where is PTFE wire commonly used?

Ans: Polytetrafluoroethylene wire finds applications in industries such as electronics, aerospace, automotive, medical, chemical processing, and more. It is used for wiring, cable assemblies, coil winding, and where high-performance electrical insulation is required.

4. What are the advantages of using PTFE wire?

Ans: Below are some advantages of this wire:

- Excellent electrical insulation.

- Wide temperature range suitability.

- Resistance to chemicals and solvents.

- Low friction and nonstick properties.

- High dielectric strength.

- Long-term reliability.

5. What are some common sizes and configurations of PTFE wire?

Ans: PTFE wire comes in various sizes and configurations, including different gauges (AWG sizes), single-core or multi-core, shielded or unshielded, and color-coded variations for easy identification.

6. Is PTFE wire safe for food and medical applications?

Ans: PTFE is considered safe for food contact and medical applications due to its non-toxic and non-reactive properties. It is often used in medical devices and equipment as well as in food processing and packaging equipment.

7. Can PTFE wire be used in high-frequency applications?

Ans: Yes, Polytetrafluoroethylene wire is suitable for high-frequency applications, such as RF and microwave devices, because of its stable electrical properties at high frequencies and low signal loss characteristics.

8. Is PTFE wire expensive?

Ans: PTFE wire can be more expensive than some other types of wire due to its unique properties and manufacturing processes. However, its high-performance characteristics often justify the cost in applications where reliability and performance are critical.

9. How is PTFE wire different from PVC or silicone-insulated wire?

Ans: PTFE wire differs from PVC (polyvinyl chloride) and silicone-insulated wire in terms of its higher temperature resistance, superior chemical resistance, and electrical properties. PVC is less heat-resistant, while silicone offers good flexibility but may not match PTFEs high-temperature capabilities.

10. Can PTFE wire be soldered easily?

Ans: Yes, Polytetrafluoroethylene wire can be soldered, but it may require special high-temperature solder and flux due to its high-temperature resistance. Proper soldering techniques and equipment should be used to avoid damaging the insulation.

11. Can PTFE wire withstand exposure to moisture and humidity?

Ans: Yes, PTFE wire is moisture-resistant and maintains its electrical properties even when exposed to moisture and humidity. However, it is essential to ensure proper sealing of connections to prevent moisture ingress.

12. Is PTFE wire recyclable?

Ans: Polytetrafluoroethylene itself is difficult to recycle due to its high chemical stability. However, some recycling processes exist for PTFE products, although they are less common than recycling processes for other materials like metals or plastics.

13. How can I store PTFE wire to maintain its properties?

Ans: Polytetrafluoroethylene wire should be stored in a dry and cool environment, away from direct sunlight, extreme temperatures, and moisture. Proper storage helps maintain its electrical and physical properties over time.

Exceptional High-Temperature Insulation

The PTFE Wire is tailored for extreme environments, offering a continuous operating temperature range from -65C up to 260C. This makes it ideal for demanding applications in aerospace, medical, and heavy-duty industrial settings. Its insulation properties ensure safe and stable performance under high heat and electrical stress.

Premium Conductivity and Flexibility

Engineered with copper, tinned, or silver-plated copper conductors, PTFE Cables provide excellent electrical conductivity and insulation resistance. Flexible constructions, available in single or multi-core variants, make installation easier in compact or complex assemblies while maintaining high mechanical strength.

Versatile and Customizable Applications

Our PTFE Wires support a wide range of usesmotors, transformers, control panels, and high-frequency electronicswith voltage types (250V, 600V, 1000V) and multiple cross-sections (0.25 mm to 95 mm). Custom lengths, colors, and terminations are available, ensuring a perfect fit for diverse specifications and industry standards.

FAQs of PTFE Wire | Teflon Cable:

Q: How is PTFE Wire different from regular PVC or rubber insulated cables?

A: PTFE (Teflon) Wire exceeds standard cables in temperature tolerance, operating reliably from -65C to 260C, and provides superior resistance to chemicals, oils, and moisture. Its high dielectric strength and excellent flexibility surpass that of common PVC or rubber-insulated cables, making it suitable for critical and harsh environments.Q: What is the typical process for selecting the correct PTFE Wire for my application?

A: To select the right PTFE Wire, consider the required voltage rating (250V, 600V, 1000V), current capacity (based on cross-sectional area), environmental conditions (temperature, chemicals), and desired core type (single or multi-core). Our technical team can assist in recommending the optimal size, conductor type, and customization for your application.Q: Where can PTFE Teflon Cables be used, and why are they preferred?

A: PTFE Teflon Cables are used in aerospace, medical devices, motors, transformers, control panels, and electronics. They are preferred due to their high temperature resistance, electrical insulation, flame retardant properties, and durability, which make them reliable in both standard and highly demanding industrial environments.Q: What are the available sizes, colors, and customization options?

A: PTFE Wire is available in cross-sectional diameters from 0.25 mm to 95 mm, custom lengths (commonly 100 m rolls), and core types (single or multi-core). White is standard, but other colors and custom terminations (lugs/terminals) are available upon request to meet specific project needs.Q: How does PTFE insulation benefit high-frequency and high-voltage applications?

A: PTFE insulation provides excellent dielectric strength (>20 kV/mm) and stable electrical properties up to 100 MHz+, minimizing signal loss and electrical leakage. This makes it ideal for high-frequency and high-voltage settingsensuring safe, efficient performance even in compact or sensitive equipment.Q: What is the warranty and quality assurance for PTFE Wire?

A: Our PTFE Wires come with a standard manufacturer warranty. They are engineered and tested to meet stringent industrial and international standards, ensuring consistent reliability, safety, and durability across all supplied products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese