- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- Fire Resistant Sleeve

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Polyurethane Fiberglass Sleeve

- Fire Sleeves

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Eurotherm Laminated Nomex Paper NPN

- Laminated Fleece Paper

- Electrical Insulating Paper

- Saturated Fleece Paper

- Laminated Aramid Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Pure Aramid (Nomex) Paper

- Electrical Insulation Papers and Laminates

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

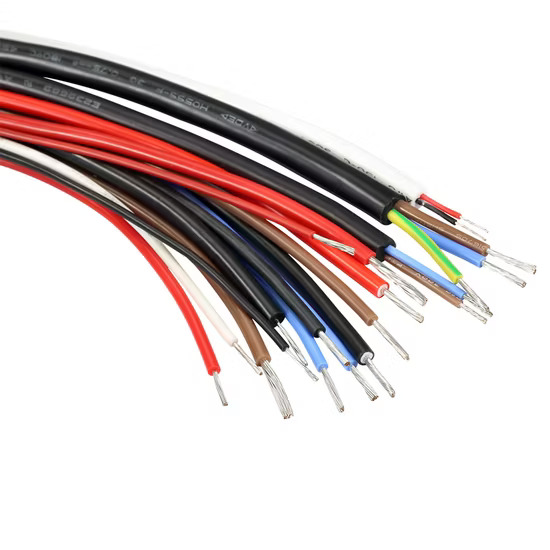

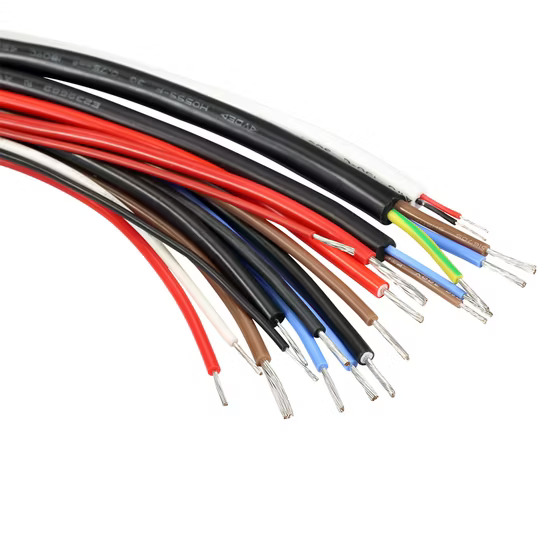

Silicon Rubber Cable

19.0 INR/Meter

Product Details:

- Product Type High-Temperature Electrical Cable

- Material High-Grade Silicone Rubber with Tinned Copper Conductor

- Color Black, White (custom colors available on request)

- Application Motors, Transformers, Heaters, Appliances, Automotive & Electrical Equipment

- Shape Cylindrical

- Density ~1.7 2.0 (approx.) Gram per cubic centimeter(g/cm3)

- Hardness Flexible, Shore A ~ 60 5

- Click to view more

X

Silicon Rubber Cable Price And Quantity

- 19.0 INR/Meter

- 1 Meter

- 27.00 - 30.00 INR/Meter

Silicon Rubber Cable Product Specifications

- Cylindrical

- Flexible, Shore A ~ 60 5

- Black, White (custom colors available on request)

- High-Temperature Electrical Cable

- ~1.7 2.0 (approx.) Gram per cubic centimeter(g/cm3)

- High-Grade Silicone Rubber with Tinned Copper Conductor

- Motors, Transformers, Heaters, Appliances, Automotive & Electrical Equipment

Silicon Rubber Cable Trade Information

- 3 Days

- Africa, Western Europe, Asia, Australia, Central America, Middle East, South America, Eastern Europe, North America

- All India

Product Description

Silicon Cable has high flexibility and electrical performance, but it also has basic flaws that make it unsuitable for many battery cable applications in cars and commercial vehicles. The innate fire-resistant qualities of silicone, a rare earth material, place it among the most dependable cables when it comes to heat resistance. Silicon Cable substance can withstand negative temperatures between 60 and 250 degree centigrade. The exceptional thermal range of silicone insulated cables is - 90 to 200 degree centigrade and above. This is safe to use.

Silicon Cable Features:

1. Silicone cables have a reputation for having exceptional heat resistance. They can survive a large temperature range without losing their electrical performance, frequently between - 60 and 200 degree centigrade.

2. Silicone rubbers natural flexibility makes it simple to bend, twist, and install these cables even in cramped locations or difficult settings.

3. Electrical Insulation: Silicone rubber offers efficient electrical insulation that, even in hot environments, prevents electrical leakage and upholds signal integrity.

4. Silicone cables are suitable for situations where exposure to corrosive substances is a problem since they display resistance to a variety of chemicals, oils, solvents, and acids.

5. Silicone rubber is naturally resistant to UV and weather, thus these cables can be used both inside and outside without deteriorating over time.

6. These cables are protected from abrasion and physical stressors by the silicone rubbers long-lasting nature and high tensile strength.

7. Many silicone cables have the ability to self-extinguish and stop the spread of flames, which increases safety in the event of a fire.

Benefits of Silicon Cable:

1. Silicone cables can be used in a wide range of applications in the automotive, aerospace, industrial machinery, and other industries thanks to their high temperature resistance, flexibility, and numerous protective qualities.

2. Durability and dependability of silicone cables translate to longer service lives and less maintenance requirements because they are made to resist challenging environments.

3. These cables are perfect for high-temperature settings, such as the engine compartments of vehicles or industrial machinery, where ordinary cables could deteriorate.

4. Silicone cables offer resistance to corrosive substances that could damage other cable types, making them ideal for locations where exposure to chemicals is likely.

5. Silicone cables suppleness makes installation simple, especially when sophisticated routing or small bends are needed.

6. These cables can be used for a variety of tasks, responding to different applications with their special blend of qualities, from household wiring to industrial gear.

FAQ:

1. Why are silicone cables utilised, in number one?

Ans: Silicone cables are used for electrical wiring in situations where it is necessary for the cables to be flexible, resistant to high temperatures, and shielded from chemicals, UV rays, and environmental elements.

2. What range of temperatures can silicone cables withstand?

Ans: Silicone cables are excellent for areas with intense heat or cold because of their usual temperature range of - 60 to 200 degree centigrade.

3. Which sectors profit from the use of silicone cables?

Ans: Silicone cables are useful in sectors including automotive, aircraft, industrial machinery, and renewable energy, where endurance to high temperatures and challenging environments is essential.

4. Are silicone cables resistant to UV radiation and chemical exposition?

Ans: Silicone cables can be used in applications in harsh environments because of their resilience to chemicals, oils, solvents, and UV light.

5. What benefits do silicone cables provide over standard cables?

Ans: Silicone cables are ideal for applications in a variety of industries and harsh environments because of their exceptional heat resistance, flexibility, chemical protection, UV resistance, and durability.

Versatile Application for Industrial Needs

Silicon cables are engineered to meet the demands of motors, transformers, heaters, appliances, and automotive as well as electrical equipment. They offer excellent flexibility and heat resistance, making them ideal for environments where reliable insulation and durability are paramount. Indian manufacturers and distributors supply these cables nationwide for diverse industrial sectors.

Flexible Material with Superior Performance

Manufactured using high-grade silicone rubber and tinned copper conductor, these cables deliver outstanding flexibility with a Shore A hardness of approximately 60. Their cylindrical shape and adjustable color options allow seamless integration into customized setups, ensuring compatibility with a wide range of electrical systems and devices.

Custom Solutions and Quality Assurance

Suppliers in India can provide silicone cables in black, white, or custom colors upon request. Every batch is produced to rigorous standards, ensuring density between 1.7 and 2.0 g/cm for consistent physical and electrical properties. The quality material and process assure long-term reliability and safety for all electrical installations.

FAQs of Silicon Cable | Silicon Rubber Cable:

Q: How are silicon rubber cables typically used in industrial applications?

A: Silicon rubber cables are predominantly used in motors, transformers, heaters, appliances, automotive systems, and electrical equipment because of their flexibility, heat resistance, and robust insulation properties.Q: What are the benefits of selecting high-grade silicone rubber with tinned copper conductor for cables?

A: High-grade silicone rubber offers superior flexibility and thermal stability, while the tinned copper conductor ensures optimal conductivity and corrosion resistance, resulting in long-lasting and high-performance cables.Q: When should I consider custom color options for silicon cables?

A: Custom color options are ideal when cables need to be coded for specific functions or integrated into unique environments; suppliers in India can accommodate such requests to suit particular design or identification requirements.Q: Where can I source silicon rubber cables in India?

A: Silicon rubber cables are available through a network of distributors, exporters, importers, manufacturers, suppliers, and traders throughout India, offering widespread access for various industrial and commercial needs.Q: What is involved in the manufacturing process of these silicon cables?

A: The cables are made by extruding high-grade silicone rubber over a tinned copper conductor in cylindrical form, and tailored in hardness, density, and color based on industry standards and customer specifications.Q: How does the cables Shore A hardness and density affect its performance?

A: A Shore A hardness of approximately 60 (5) provides a balanced flexibility and toughness, while the density range of 1.72.0 g/cm contributes to consistent mechanical strength and insulation properties.Q: What advantages do silicon rubber cables offer over traditional cable materials?

A: Silicon rubber cables deliver better performance in high-temperature and flexible environments, maintaining insulation integrity and electrical reliability where traditional cables may degrade or fail.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese