- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Polyester Expandable Braided Sleeves

- Insulation Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Polyurethane Fiberglass Sleeve

- Fire Sleeves

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Pure Aramid (Nomex) Paper

- Electrical Insulation Papers and Laminates

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

Epoxy Fiberglass Sheet

50.0 INR/Kilograms

Product Details:

- Size 610 mm X 1020 mm, 1020 mm X 1020 mm

- Product Type Epoxy Fiberglass Sheet

- Material Fiberglass

- Thickness 0.50 to 100 Millimeter (mm)

- Application Motors / Transformers

- Color Yellow

- Click to view more

X

Epoxy Fiberglass Sheet Price and Quantity

- 50.0 INR/Kilograms

- 50 Kilograms

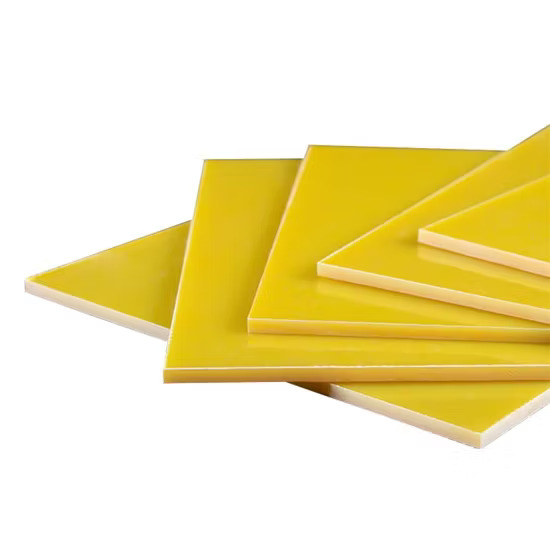

Epoxy Fiberglass Sheet Specification

- Epoxy Fiberglass Sheet

- 0.50 to 100 Millimeter (mm)

- Yellow

- Fiberglass

- Motors / Transformers

- 610 mm X 1020 mm, 1020 mm X 1020 mm

Epoxy Fiberglass Sheet Trade Information

- 1000 Kilograms Per Month

- 3 Days

- Middle East, Central America, South America, Western Europe, Africa, Asia, Australia, North America, Eastern Europe

- All India

Product Description

Epoxy fibreglass sheets are composite materials that mix epoxy resin with fibreglass reinforcement. They are also known as epoxy glass laminate sheets or epoxy glass cloth sheets. Due to their superior mechanical strength, chemical resistance, and electrical insulation, these sheets are utilised extensively across a variety of sectors.

Composition Of Epoxy Fibreglass Sheet:

Epoxy-impregnated layers of woven fibreglass fabric make up fiberglass epoxy sheets. To produce a sturdy and rigid composite material, the resin is heated and compressed during curing. Epoxy and fibreglass are combined to create a sheet with a balance of mechanical and electrical insulating qualities.

Epoxy Fibreglass Sheet Features:

1. Epoxy fiberglass sheets are ideal for applications where avoiding electrical conduction is important because to their superior electrical insulation qualities. They are utilised in electrical machinery and parts to guard against short circuits and guarantee security.

2. Fiberglass epoxy sheets have strong mechanical strength because to the fibreglass reinforcing. They are useful for structural and load-bearing applications because they can tolerate mechanical stress, collisions, and vibrations.

3. Epoxy fiberglass sheets are well-suited for use in a variety of chemical environments, including those involving acids, bases, and solvents. They are suitable for locations where exposure to corrosive substances is a problem because to their chemical resistance.

4. These sheets can withstand moderate temperatures and have good thermal stability. They are suitable for applications with temperature changes.

5. Epoxy fibreglass sheets maintain their dimensions and shape even when subjected to mechanical and thermal stress, which increases their dependability over time.

6. Depending on the formulation, some epoxy fiberglass sheets may have the ability to resist flames, providing an added measure of security in applications where fire resistance is crucial.

Applications Of Fibreglass Epoxy Sheet:

1. Electrical Industry: Epoxy fibreglass sheets are frequently used in the electrical industry to insulate electrical parts such as switchgear, busbars, insulators, and electrical cabinets. They guard against short circuits and electrical failure.

2. Mechanical Engineering: These sheets are used in mechanical engineering for support structures, bearings, and gears - components that need to be highly stable and strong.

3. Automotive and aircraft Applications: Due to its lightweight design, electrical insulation, and mechanical toughness, fiberglass epoxy sheets are utilised in automotive and aircraft applications.

4. Construction: Because of their mechanical robustness and design versatility, they are utilised in construction for cladding, facades, and panels.

5. Marine: Due to its resistance to corrosion and moisture, epoxy fibreglass sheets are utilised in marine applications for boat hulls, decks, and interior parts.

6. Industrial Equipment: Due to their chemical resistance and mechanical qualities, they are employed in manufacturing equipment, chemical tanks, and enclosures.

FAQ:

1. What is the composition of epoxy fiberglass sheets?

Ans: The layers of woven fibreglass fabric that make up fiberglass epoxy sheets are impregnated with epoxy resin. These components are combined to create a composite material that is sturdy, long-lasting, and electrically insulating.

2. Why Should I Use Epoxy Fiberglass Sheets?

Ans: The best electrical insulation, highest mechanical strength, chemical resistance, thermal stability, and dimensional stability are all features of epoxy fiberglass sheets. They are suitable for use in electrical, mechanical, and structural engineering because of these characteristics.

3. How are fiberglass epoxy sheets utilised in the electrical sector?

Ans: In parts like switchgear, insulators, and electrical cabinets, fiberglass epoxy sheets are frequently utilised for electrical insulation. They stop electrical conduction, reduce the chance of short circuits, and guarantee that electrical equipment is used safely.

4. What uses Epoxy Fiberglass Sheets are advantageous for?

Ans: The answer is that these products are used in many different sectors. Wherever a blend of electrical insulation and mechanical strength is required, they are employed in construction materials, marine constructions, industrial equipment, and more.

5. Are Fiberglass Epoxy Sheets Chemical Resistant?

Ans: Yes, these products provide good chemical resistance to a variety of acids, bases, and solvents. They are suitable for use in areas where exposure to corrosive substances is a concern due to their chemical resistance.

Premium Insulation for Motors and Transformers

Our Epoxy Fiberglass Sheets are specifically engineered for high-performance insulation in motors and transformers. The epoxy-resin and fiberglass composite structure delivers excellent dielectric properties, making them an ideal choice for environments demanding electrical safety and resilience. These sheets maintain stability and integrity even in challenging industrial settings.

Versatile Thickness Options

Available in a wide thickness spectrum from 0.50 to 100 mm, these sheets accommodate various technical requirements. Whether for intricate winding insulation or robust transformer barriers, their adaptability ensures suitability for multiple applications. This variety supports customization, giving manufacturers and engineers the flexibility they need.

Reliable Supply Network Across India

As a distributor, exporter, importer, manufacturer, supplier, and trader in India, we guarantee consistent quality and prompt delivery. Our extensive network enables seamless procurement, whether in metropolitan or remote zones, ensuring your business experiences uninterrupted operations and quick support.

FAQs of Epoxy Fiberglass Sheet:

Q: How are Epoxy Fiberglass Sheets used in motors and transformers?

A: Epoxy Fiberglass Sheets serve as electrical insulation barriers within motors and transformers, preventing short circuits and enhancing safety by separating conductive components.Q: What is the process for manufacturing Epoxy Fiberglass Sheets?

A: The sheets are produced by layering fiberglass with epoxy resin under controlled heat and pressure, resulting in a strong, durable laminate with outstanding electrical and mechanical properties.Q: When should I choose a specific thickness for my application?

A: Selecting the appropriate thickness depends on your devices electrical load and mechanical stress requirements. For compact motor windings, thinner sheets are ideal, while thicker sheets provide robust insulation for transformers.Q: Where can I purchase Epoxy Fiberglass Sheets in India?

A: You can buy these sheets through authorized distributors, exporters, importers, manufacturers, suppliers, and traders located throughout India, ensuring accessibility across regions.Q: What are the benefits of using Epoxy Fiberglass Sheets?

A: These sheets provide excellent electrical insulation, high mechanical strength, thermal stability, and resistance to moisture and chemicals, enhancing equipment safety and durability.Q: How should Epoxy Fiberglass Sheets be installed in equipment?

A: Installation involves precisely cutting the sheets to fit, followed by securing them in place with fasteners or adhesives, ensuring proper alignment for maximum insulation and protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese