- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Polyester Expandable Braided Sleeves

- Insulation Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Polyurethane Fiberglass Sleeve

- Fire Sleeves

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Pure Aramid (Nomex) Paper

- Electrical Insulation Papers and Laminates

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

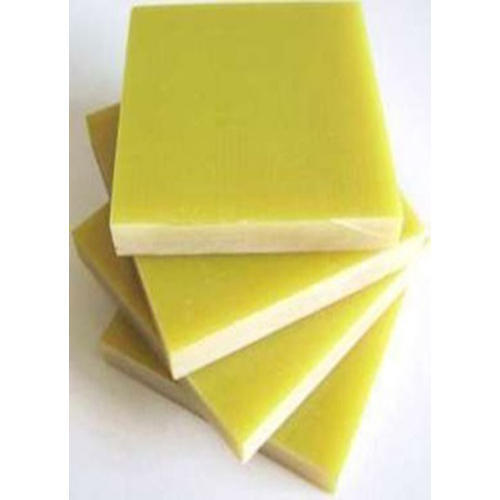

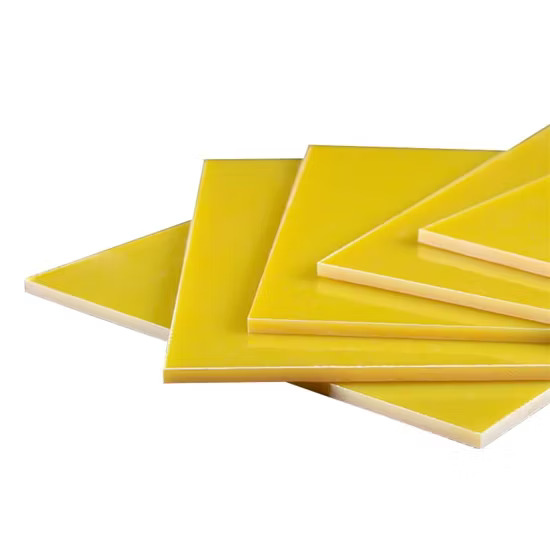

FRP Sheet

50.0 INR/Kilograms

Product Details:

- Material SMC/FRP

- Thickness 1 Millimeter (mm)

- Application Industrial

- Breakdown Voltage 7 Volt (V)

- Color Yellow

- Click to view more

X

FRP Sheet Price And Quantity

- 1 Kilograms

- 50.0 INR/Kilograms

FRP Sheet Product Specifications

- Yellow

- 1 Millimeter (mm)

- Industrial

- SMC/FRP

- 7 Volt (V)

FRP Sheet Trade Information

- 1000 Kilograms Per Month

- 3 Days

- All India

Product Description

Due to their strength, durability, and adaptability, SMC (Sheet Moulding Compound) and FRP (Fiber-Reinforced Plastic) sheets are both composite materials utilised in a variety of applications. An overview of SMC/FRP sheets is given below:

Sheets made of SMC (Sheet Moulding Compound)

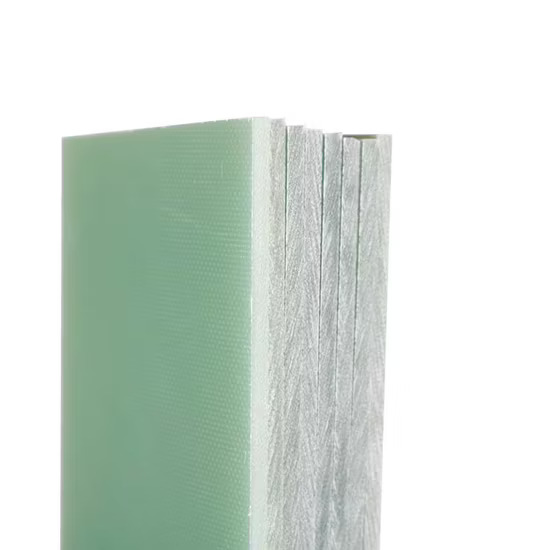

SMC is a composite material that is formed by mixing chopped glass fibres with a resin matrix, usually polyester, and compressing and curing the resulting combination to form a robust and long-lasting sheet. Due to their exceptional mechanical and electrical qualities, SMC sheets are frequently employed for the production of numerous components.

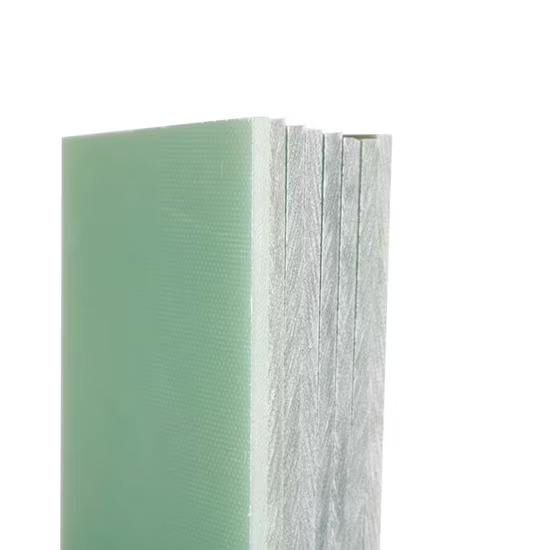

Sheets made of FRP (fiber-reinforced plastic)

Glass fibres are encased in a plastic matrix, such as polyester or epoxy resin, to create FRP sheets, also referred to as fiberglass-reinforced plastic sheets. Fibres and resin work together to increase a materials strength, durability, and corrosion resistance.

SMC/FRP Sheet Features:

1. High Strength: The mechanical strength of SMC and FRP sheets is well recognised. The plastic matrix gains tensile and flexural strength from the glass fibre reinforcement.

2. SMC and FRP sheets are relatively lightweight when compared to more heavy-duty materials like steel, which makes them suitable for situations where weight reduction is crucial.

3. Flexibility in design: SMC and FRP sheets can be moulded into sophisticated shapes, enabling the production of intricate and specialised components.

4. Both materials have strong electrical insulating qualities, which makes them acceptable for situations where electrical conductivity needs to be kept to a minimum.

5. Thermal Insulation: SMC and FRP sheets naturally have the ability to insulate heat, which can be useful in applications where temperature regulation is crucial.

6. Ease of Fabrication: These sheets may be machined, drilled, and cut easily with common tools.

SMC/FRP sheet applications

1. Automobiles: Due to its light weight and excellent strength, SMC sheets are utilised in body panels, hoods, and bumpers in automobiles. FRP sheets are used for structural elements and automotive interiors.

2. Construction: Due to their durability and design flexibility, SMC and FRP sheets are utilised in architectural applications such as facades, roofing, and cladding.

3. Marine: Due to their resistance to water and corrosion, FRP sheets are used often in marine applications for boat hulls, decks, and interior components.

4. Industrial Equipment: Due to their mechanical strength and chemical resistance, SMC and FRP sheets are utilised in the production of industrial equipment, storage tanks, and enclosures.

5. Aerospace: Due to its light weight and fire resistance, SMC sheets are utilised in aeroplane interiors.

6. Due to their electrical insulating qualities, these materials are utilised in electrical enclosures, panels, and cabinets.

Both SMC and FRP sheets have a wealth of benefits, making them valuable building materials in sectors needing robust, lightweight, and long-lasting components. Depending on the needs and desired qualities of a given application, SMC or FRP will be chosen.

FAQ

1. What materials are used to make FRP (fiber-reinforced plastic) and SMC (sheet moulding compound) sheets?

Ans - In order to create SMC sheets, chopped glass fibres are mixed with a resin matrix, usually polyester, before being compressed and given time to cure. Glass fibres are inserted in a plastic matrix, often made of polyester or epoxy resin, to create FRP sheets, which offer improved strength and durability.

2. Frequently Asked Questions: Why are SMC/FRP sheets useful in manufacturing?

Ans - In response, SMC and FRP sheets offer good electrical and thermal insulation qualities together with high strength, lightweight construction, corrosion resistance, and design flexibility. They are suited for a wide range of applications in many industries because to these characteristics.

3. What are some popular uses for SMC/FRP sheets?

Ans - SMC sheets are frequently used in electrical enclosures, construction materials, industrial equipment, and automobile parts. FRP sheets are used for interiors of aerospace vehicles, architectural components, and marine vessels, among other things.

4. How do SMC/FRP sheets differ from conventional materials like steel?

Ans - The strength of SMC and FRP sheets is comparable to that of steel, although they are significantly lighter. They are useful in applications where weight reduction is desired without compromising mechanical performance because of this.

5. SMC/FRP sheets: Can they be customised for certain designs?

Ans - Using common manufacturing techniques, SMC and FRP sheets can both be moulded into complex and unique designs. Due to the designs adaptability, customised components can be created to satisfy certain application needs.

Durable Yellow SMC/FRP Sheet for Industrial Applications

Designed specifically for challenging industrial environments, our yellow SMC/FRP sheets deliver excellent mechanical strength and electrical insulation. With a standard thickness of 1 mm and a breakdown voltage of 7 V, these sheets serve as robust solutions for electrical, construction, and other technical uses. Quality assurance and nationwide distribution ensure consistent performance for every project.

Nationwide Distribution & Export Services

We operate as a trusted distributor, exporter, importer, manufacturer, supplier, and trader of SMC/FRP sheets throughout India. Our streamlined supply chain ensures prompt delivery and support to meet varying industry requirements, both domestically and globally. Customized solutions are available to fulfill unique client demands.

FAQs of SMC/FRP Sheet:

Q: How are SMC/FRP sheets used in industrial applications?

A: SMC/FRP sheets are commonly utilized as insulation panels, protective barriers, and component substrates in factories and electrical systems due to their insulation capacity and mechanical robustness.Q: What is the significance of the 1 millimeter thickness for these sheets?

A: A thickness of 1 mm provides a balance between flexibility and strength, making the sheets suitable for most industrial installations without adding excessive weight or bulk.Q: When should SMC/FRP sheets be preferred over other materials?

A: These sheets are ideal when electrical insulation, corrosion resistance, and lightweight properties are required, particularly in environments where other materials may degrade or fail.Q: Where can these yellow SMC/FRP sheets be sourced in India?

A: They are available through our extensive network, which includes distribution centers and partners in major industrial hubs throughout India. Customers can contact us directly to get location-specific availability.Q: What is the breakdown voltage of the yellow SMC/FRP sheet, and why does it matter?

A: The breakdown voltage is 7 volts; this specifies the maximum electrical stress the sheet can safely withstand, ensuring it performs reliably in electrical and high-voltage installations.Q: What is the process for ordering these sheets for export or bulk supply?

A: Clients can place orders by reaching out to our sales team, specifying required dimensions and quantities. Our expert staff then coordinate logistics for prompt delivery or export, ensuring quality standards are maintained.Q: What are the benefits of choosing SMC/FRP material for industrial sheet applications?

A: SMC/FRP sheets provide exceptional durability, resistance to corrosion, low electrical conductivity, and ease of installation, making them a cost-effective solution for industrial protection and insulation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese