- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- Fire Resistant Sleeve

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Polyurethane Fiberglass Sleeve

- Fire Sleeves

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Eurotherm Laminated Nomex Paper NPN

- Laminated Fleece Paper

- Electrical Insulating Paper

- Saturated Fleece Paper

- Laminated Aramid Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Pure Aramid (Nomex) Paper

- Electrical Insulation Papers and Laminates

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

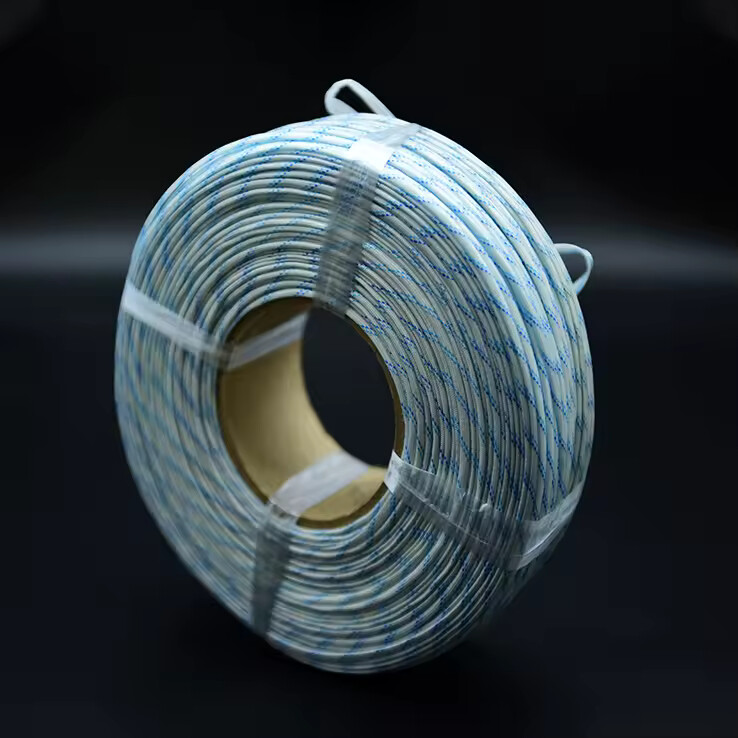

Fiberglass Sleeve ( China Sleeve )

2.0 INR/Meter

Product Details:

- Size as per requirement

- Feature Features: Excellent electrical insulation properties High flexibility and abrasion resistance Resistant to oil, moisture, and most chemicals Smooth finish for easy cable bundling Cost-effective insulation solution Usage & Applications: Cable harness protection Electrical motors and household appliances Transformers, lighting fixtures, and panels Automotive wiring and industrial machinery

- Coating Type PVC extrusion over braided fiberglass

- Layer Single braided fiberglass with PVC coating

- Density Industrial standard Gram per cubic centimeter(g/cm3)

- Installation Guideline Easy to cut, slide-on installation for cables and windings

- Product Type Fiberglass Sleeve

- Click to view more

X

Fiberglass Sleeve ( China Sleeve ) Price And Quantity

- 2.0 INR/Meter

- 1 Meter

Fiberglass Sleeve ( China Sleeve ) Product Specifications

- Cable harness protection Electrical motors and household appliances Transformers, lighting fixtures, and panels Automotive wiring and industrial machinery

- As required Millimeter (mm)

- -40 C to +125 C (PVC grade)

- Features: Excellent electrical insulation properties High flexibility and abrasion resistance Resistant to oil, moisture, and most chemicals Smooth finish for easy cable bundling Cost-effective insulation solution Usage & Applications: Cable harness protection Electrical motors and household appliances Transformers, lighting fixtures, and panels Automotive wiring and industrial machinery

- High flexibility and mechanical strength Newtons per Millimetre Squared (N/mm2)

- Up to 7 kV Volt (v)

- Low, excellent thermal insulation Watt/Meter/K (w/(m.k)

- PVC extrusion over braided fiberglass

- Easy to cut, slide-on installation for cables and windings

- -60 C to +200 C (based on coating) Celsius (oC)

- Single braided fiberglass with PVC coating

- Fiberglass Sleeve

- Up to 7 kV Ampere (A)

- 0.2 mm 2.5 mm (standard range) Millimeter (mm)

- Silicone / PVC Coated Fiberglass

- Up to 7 kV Volt (V)

- Fiberglass Sleeve

- Industrial standard Gram per cubic centimeter(g/cm3)

- as per requirement

- White, Black, Yellow

- Features: Excellent electrical insulation properties High flexibility and abrasion resistance Resistant to oil, moisture, and most chemicals Smooth finish for easy cable bundling Cost-effective insulation solution Usage & Applications: Cable harness protection Electrical motors and household appliances Transformers, lighting fixtures, and panels Automotive wiring and industrial machinery

- Up to 250 C (short-term, silicone coated type)

Fiberglass Sleeve ( China Sleeve ) Trade Information

- 3 Days

Product Description

Fiberglass Sleeve (China Sleeve)

Fiberglass Sleeve, also popularly known as China Sleeve, is a high-quality insulating product made from braided fiberglass yarn. To improve its electrical and thermal performance, the base fiberglass is coated with insulating materials such as varnish, PVC, or silicone. This combination provides excellent protection against heat, electricity, and mechanical damage, making it a preferred choice for motors, transformers, wiring harnesses, and various electrical assemblies.

Construction

-

Base material: Braided alkali-free fiberglass yarn

-

Coating:

-

Varnished type high dielectric strength, heat class B (130C), F (155C), or H (180C)

-

PVC coated type smooth surface, flexible, economical, temperature range -40C to +125C

-

Silicone coated type high thermal endurance, flexible, temperature range up to 200C continuous

-

-

Available colors: White, black, yellow, red, or as per requirement

-

Sizes: Wide range of diameters (0.5 mm to 25 mm or customized)

Technical Properties

-

Dielectric Strength (Breakdown Voltage): 1.5 kV 7 kV depending on wall thickness

-

Operating Temperature: -60C to +200C (based on coating)

-

Max Withstanding Temperature: Up to 250C (short-term, silicone coated type)

-

Tensile Strength: High mechanical strength with flexibility

-

Thermal Conductivity: Low, excellent thermal insulation

-

Surface Treatment: Smooth and uniform coating for easy installation

-

Moisture & Chemical Resistance: Resistant to oil, solvents, and common industrial chemicals

Applications

Fiberglass Sleeves are widely used in:

-

Electrical motors and transformers for insulation of winding leads and terminals

-

Generators and coils to prevent electrical leakage and mechanical wear

-

Wiring harnesses in appliances, automotive, and industrial machines

-

Cables and connections for added protection against heat, abrasion, and electrical breakdown

-

Panels and lighting equipment to ensure safe and durable wiring insulation

Advantages

-

Excellent electrical insulation with long service life

-

Superior thermal resistance suitable for high-temperature environments

-

Flexible structure allows easy cutting and installation

-

Protects wires from abrasion, oil, moisture, and heat

-

Available in multiple grades and sizes to suit different applications

Common Name

Though technically called Fiberglass Sleeve, in general industry practice and local markets it is also referred to as China Sleeve.

Robust Insulation and Flexibility

Built from single braided fiberglass with a PVC or silicone extrusion, this fibreglass sleeve ensures outstanding electrical insulation up to 7 kV. Its structure grants high tensile strength and flexibility, enabling superior protection for delicate wires and cables in demanding environments. The sleeves low heat conductivity further promotes thermal insulation, safeguarding internal cable assemblies from excessive temperature fluctuations.

Convenient Installation and Wide Applications

Designed for ease, this sleeve is simple to cut and slide onto cables or windings, with an IP20 rating when used as cable insulation. Its adaptability allows for application in cable harnesses, electric motors, transformers, lighting fixtures, panels, and various industrial machinery. This makes it suitable for manufacturers, distributors, installers, and end-users alike.

Durability and Chemical Resistance

Coated in durable PVC or silicone, the sleeve resists oil, moisture, and chemical exposure commonly found in industrial and automotive contexts. The abrasion-resistant outer layer protects cables and wiring from mechanical damage and environmental stress, assuring longevity and reliability throughout its service life.

FAQs of Fibreglass Sleeve ( China Sleeve ):

Q: How do I install the Fibreglass Sleeve on cables or windings?

A: Installation is straightforwardmeasure and cut the sleeve to the required length, then slide it over the cables or windings. Its flexibility allows easy maneuvering even in confined spaces, making it suitable for both new installations and retrofits.Q: What applications are best suited for the Fibreglass Sleeve?

A: This product excels in cable harness protection, electrical motors, household appliances, transformers, lighting fixtures, automotive wiring, and industrial machinery, owing to its high voltage insulation, abrasion resistance, and flexibility.Q: When should I choose a silicone versus PVC coated sleeve?

A: Choose a silicone-coated sleeve if you require short-term exposure to temperatures up to 250C, such as in certain industrial or automotive scenarios. The PVC coated variant is ideal for general insulation needs, withstanding temperatures from -40C to +125C.Q: Where can the Fibreglass Sleeve be installed?

A: It is suitable for installation wherever electrical insulation and cable protection are needed, including indoor electrical panels, machinery, automotive wiring trays, and within household appliances, provided the environmental conditions match its ratings.Q: What is the process for selecting the right size and thickness of the sleeve?

A: Determine the diameter and length needed to accommodate your cables or windings. Standard thicknesses range from 0.2 mm to 2.5 mm, and custom widths are available. Ensure the sleeve fits snugly without impeding flexibility or placing excessive pressure on the wires.Q: How does the Fibreglass Sleeve benefit cable assemblies?

A: It provides robust insulation, minimizes risk of electrical breakdown up to 7 kV, boosts mechanical protection, ensures a smooth bundle finish, and prolongs cable service life in an economical manner.Q: What are the usage guidelines for maximum performance and safety?

A: Use the sleeve within specified voltages and temperature limits. Install in dry, clean environments to maximize its IP20 rating, and avoid exposure to conditions outside its chemical resistance capacity for the best results.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese