- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Acrylic Fiberglass Sleeving

- Varnished Fiberglass Sleeve F Class

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

Polyurethane Fiberglass Sleeve

2.0 INR/Meter

Product Details:

- Product Type INSULATION SLEEVE

- Material VARNISHED FIBERGLASS SLEEVE, SILICON SLEEVE

- Rated Voltage 5 Volt (V)

- Application TRANSFORMER, BATTERY, MOTORS, PANELS

- Breakdown Voltage 7 Volt (V)

- Color NATURAL, BLACL, BLUE, YELLOW, RED, WHITE. GREEN

- Click to view more

X

Polyurethane Fiberglass Sleeve Price And Quantity

- 1 Meter

- 2.0 INR/Meter

Polyurethane Fiberglass Sleeve Product Specifications

- TRANSFORMER, BATTERY, MOTORS, PANELS

- 7 Volt (V)

- 5 Volt (V)

- VARNISHED FIBERGLASS SLEEVE, SILICON SLEEVE

- INSULATION SLEEVE

- NATURAL, BLACL, BLUE, YELLOW, RED, WHITE. GREEN

Polyurethane Fiberglass Sleeve Trade Information

- Mumbai / Bhiwandi

- Telegraphic Transfer (T/T), Paypal, Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Delivery Point (DP)

- 1000000 Meter Per Month

- 1 Days

- No

- Free samples are available

- 100 meters roll / pack

- Asia, Australia, Western Europe, Middle East, Central America, North America, South America, Eastern Europe, Africa

- All India

- CE / RoHS / UL

Product Description

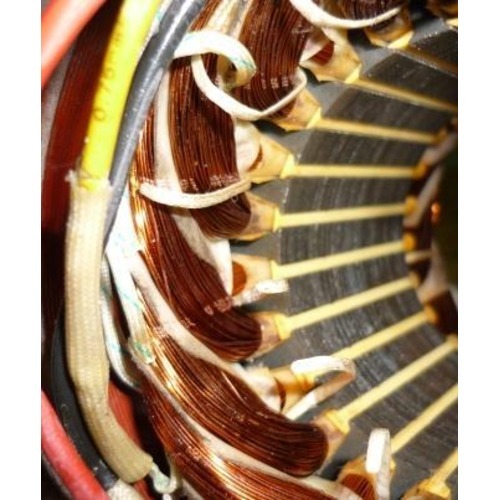

PU Sleeves Durable and Flexible Insulation for Modern Applications

In todays electrical and mechanical industries, insulation and protection of cables, wires, and components are critical for safety, efficiency, and long service life. One of the most versatile solutions available is the PU (Polyurethane) Sleeve. Known for its high flexibility, wear resistance, and durability, PU Sleeves are widely used across industries ranging from automotive to electronics and general engineering.

What is a PU Sleeve?

A PU Sleeve is a tubular insulating product made from polyurethane material, either as a coated fiberglass base or as a standalone extruded sleeve. Polyurethane is known for its exceptional toughness, abrasion resistance, and elasticity, making it ideal for demanding applications where both mechanical and electrical protection are required.

Technical Properties of PU Sleeves

PU Sleeves combine mechanical strength with electrical insulation, offering excellent protection for cables and wires in challenging environments.

-

Material: Polyurethane (with or without fiberglass reinforcement)

-

Color Options: Natural, Transparent, Yellow, Red, Black, or customized

-

Operating Temperature: -40C to +125C (continuous)

-

Breakdown Voltage: 1.5 kV 4 kV (depending on thickness)

-

Tensile Strength: High, resists cuts and abrasion

-

Hardness: Shore A 8595 (depending on grade)

-

Chemical Resistance: Resistant to oils, fuels, solvents, and most industrial chemicals

-

Flexibility: Excellent bending and folding capability without cracking

-

Moisture Resistance: Very low water absorption

Key Features of PU Sleeves

-

Outstanding abrasion resistance, much higher than PVC or varnished fiberglass sleeves

-

Maintains flexibility at both low and moderate high temperatures

-

Provides good electrical insulation with stable dielectric properties

-

Excellent resistance to oils, fuels, and chemicals, suitable for harsh environments

-

Lightweight and easy to handle, cut, and install

-

Long service life due to durable mechanical performance

Applications of PU Sleeves

PU Sleeves are used in a wide variety of industries thanks to their balance of mechanical durability and electrical insulation.

-

Automotive Industry: Wiring harness protection, fuel line insulation, cable bundling

-

Electrical Motors & Transformers: Secondary insulation for winding leads

-

Electronics & Appliances: Protection for wires and connections inside equipment

-

Industrial Machinery: Cable protection in moving or vibrating parts where abrasion resistance is crucial

-

Aerospace & Railway: Lightweight and tough insulation for wiring and cables

-

General Engineering: Protective covering for rods, rollers, and fittings

Why Choose PU Sleeves?

Compared to other sleeves such as PVC or Silicone, PU Sleeves stand out in applications where abrasion resistance and mechanical durability are more critical than extreme temperature resistance. They are an economical yet high-performance choice for industries needing reliable insulation and long-term protection.

Superior Electrical Insulation

Our PU Sleeves guarantee optimal insulation for electrical components, ensuring safety and stability in transformers, batteries, motors, and control panels. Their durable construction helps prevent short circuits and provides long-lasting protection even in demanding environments.

Wide Range of Colors and Applications

The polyurethane fiberglass sleeves come in multiple colors: natural, black, blue, yellow, red, white, and green. This diversity allows for easy identification and organization in complex electronic assemblies, enhancing efficiency in installation and maintenance.

FAQs of Polyurethane Fiberglass Sleeve | PU Sleeve:

Q: How is the Polyurethane Fiberglass Sleeve installed in electrical equipment?

A: The sleeve is typically slipped over wires or components to provide insulation. Installation should be done after cutting the sleeve to the desired length and ensuring a snug fit for effective protection.Q: What materials are used in manufacturing these PU Sleeves?

A: These sleeves are crafted from varnished fiberglass and silicon, ensuring robust insulation, thermal resistance, and durability in various electrical environments.Q: When should I use a PU Sleeve in my electrical setup?

A: PU sleeves are recommended whenever extra electrical insulation is required, especially in settings such as transformers, batteries, motors, and control panels prone to voltage fluctuations.Q: Where can I purchase these polyurethane fiberglass sleeves in India?

A: As a recognized distributor, exporter, supplier, importer, manufacturer, and trader, our PU sleeves are available throughout India, ensuring easy access for varied industrial needs.Q: What is the process for selecting the correct sleeve color and type for my application?

A: Consider the voltage rating, breakdown voltage, and environment of use; then select the color for identification purposes or system organization. Consulting our technical team can help ensure you choose the right type and grade for your specific requirements.Q: How does using a PU Sleeve benefit my electrical system?

A: PU sleeves enhance the safety and reliability of your electrical system by providing superior insulation, reducing the risk of breakdowns or short circuits, and enabling clear identification of wires and components through color coding.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese