- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Electrical Insulating Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Laminated Fleece Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

Fire Resistant Sleeve

20.0 INR/Meter

Product Details:

- Size Standard

- Surface Treatment Polished.

- Material Silicone, fiberglass

- Application Electrical Appliances

- Color Red

- Click to view more

X

Fire Resistant Sleeve Price and Quantity

- 20.0 INR/Meter

- 1 Meter

Fire Resistant Sleeve Specification

- Polished.

- Red

- Silicone, fiberglass

- Electrical Appliances

- Standard

Fire Resistant Sleeve Trade Information

- 1000 Meter Per Month

- 3 Days

- Asia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Australia

- All India

Product Description

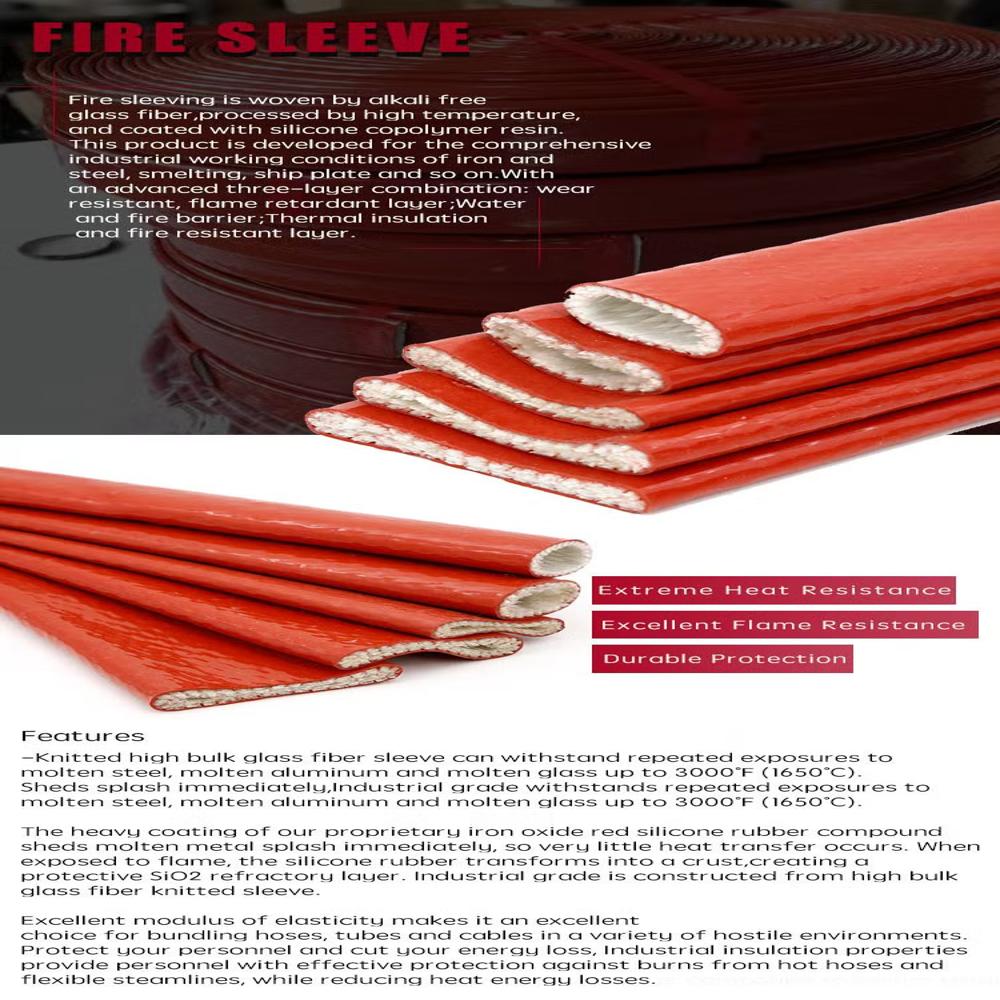

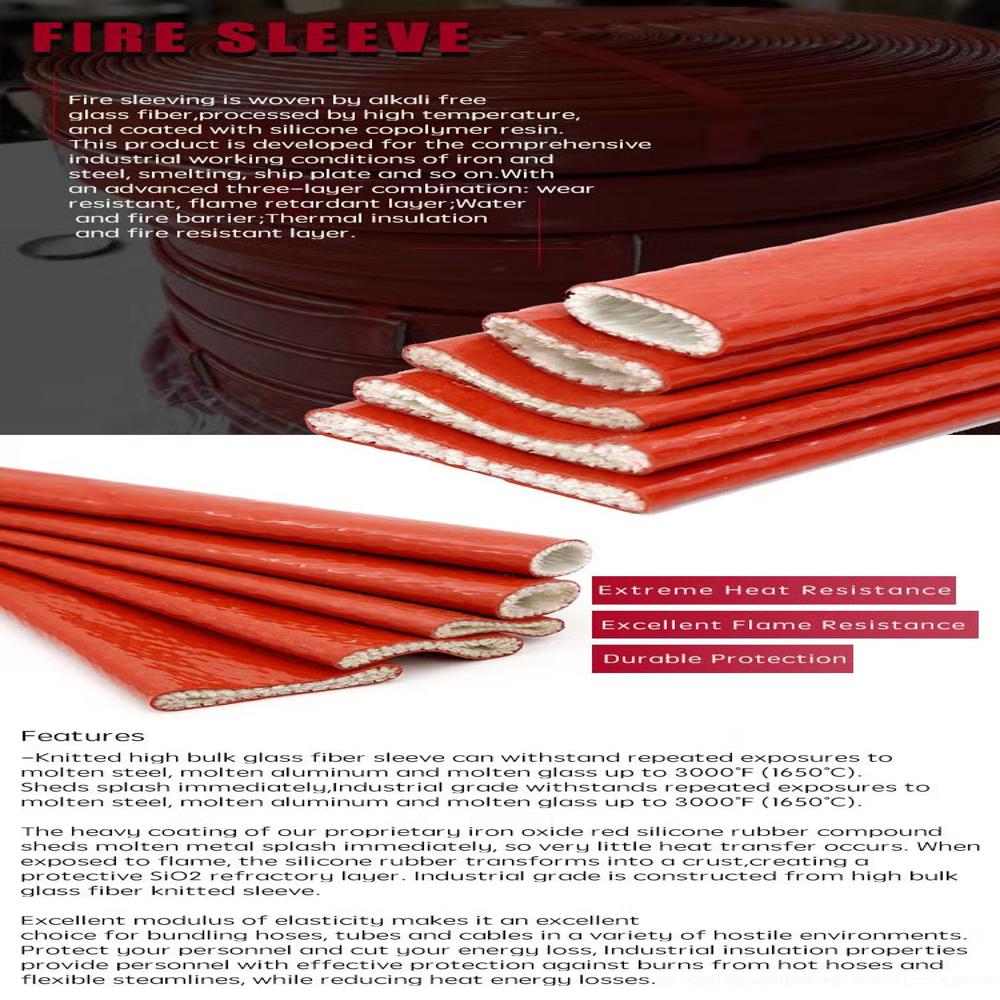

A protective covering made to offer a barrier against extreme heat, flames, sparks, and heat-related hazards is referred to as a fire-resistant sleeve, flame-resistant sleeve, or fireproof sleeve. In many different industries, these sleeves are frequently employed to protect wires, cables, hoses, and other components from potential fire hazards.

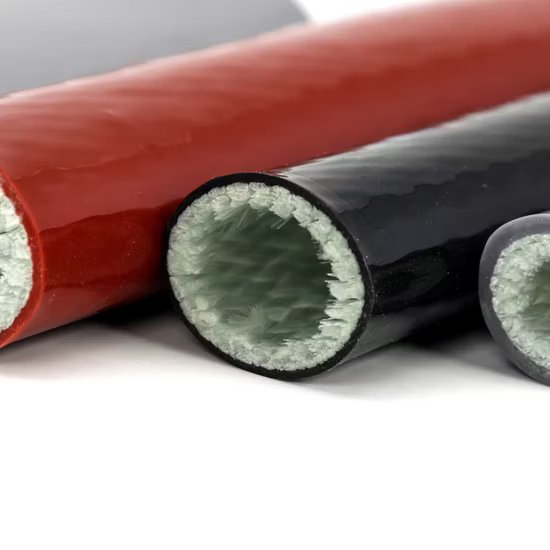

Material Composition:

Specialised materials that can endure intense heat and flames are often used in the construction of fire-resistant sleeves. These materials frequently consist of fibreglass coated with silicone, fire-resistant fabrics, or other high-tech textiles that provide both thermal insulation and fire protection.

Characteristics of Fire Resistant Sleeve:

1. A fire-resistant sleeves main purpose is to thwart the spread of heat and flames. Direct contact with flames and high temperatures wont damage these sleeves.

2. Fire-resistant sleeves offer thermal insulation, which lessens the amount of heat that is transferred from the outside environment to the enclosed components. This prevents cables and wires from melting, deteriorating, or igniting nearby items.

3. These sleeves frequently provide mechanical protection against abrasion, collisions, and other physical stressors that could harm cables and wires in addition to flame resistance.

4. Fire-resistant sleeves are essential in emergency situations because they help to confine fires and stop them from spreading through cables and wires.

5. Because these sleeves are made to function well over a broad temperature range, they can be used in applications involving intense heat or rapid temperature changes.

6. Fire-resistant sleeves may frequently be modified to fit a variety of projects by changing their size, length, and other characteristics.

Fire Resistant Sleeve Specifications:

1. Heat Resistant: Yes

2. Material: Silicone, fiberglass

3. Continuous operating temperature: 310 degree centigrade

4. Max short term exposure: 1600 degree centigrade

5. Resistance: Fire resistance/ Flame Retardant/ Insulation/ water Proof/ grease Proof/ acid And Alkali Resistant

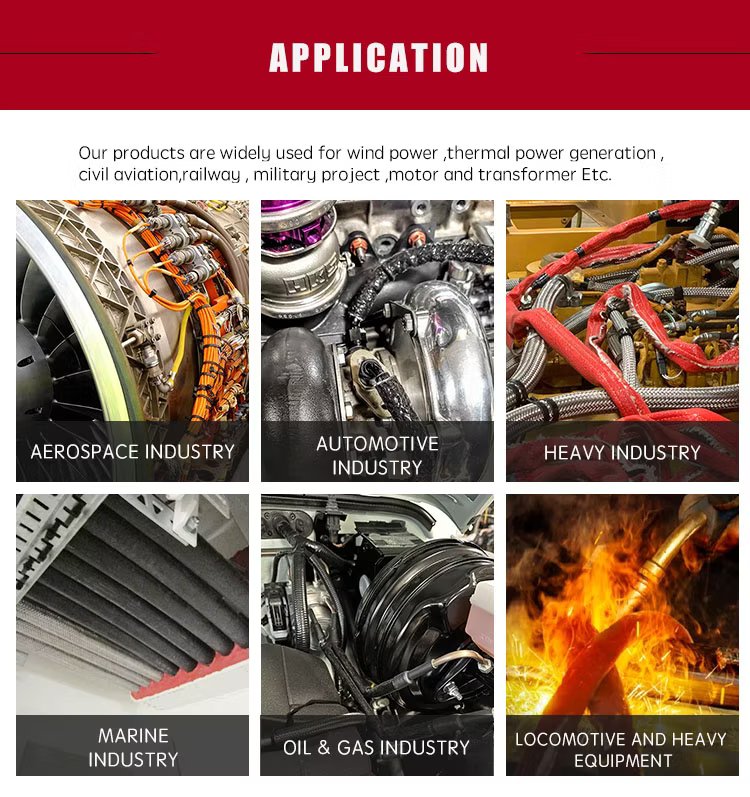

Fire Resistant Sleeve Applications:

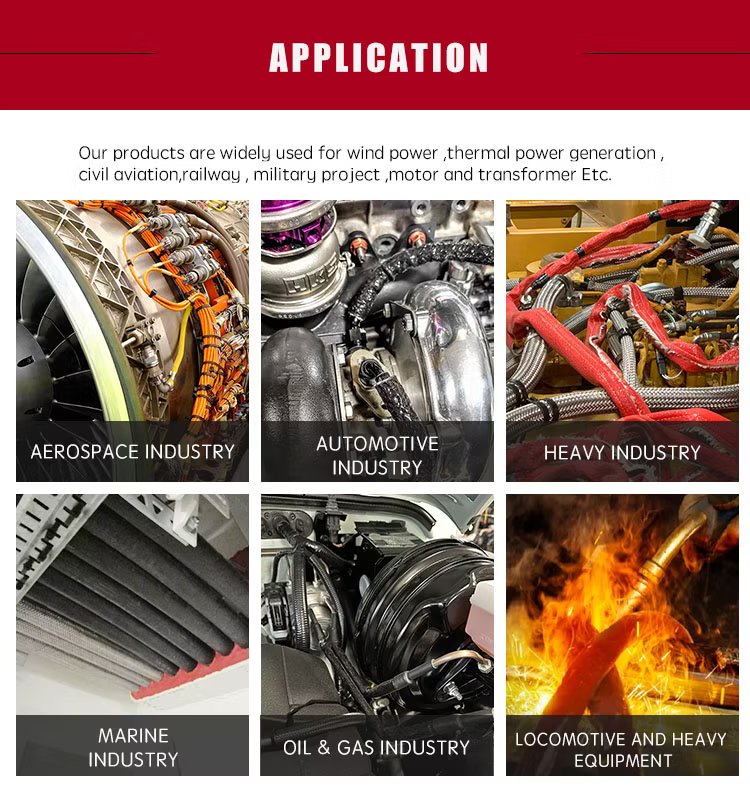

1. Aviation and space

2. Automobile production

3. Gas and oil

4. Generation and distribution of power

5. Equipment and machinery used in industry

Installation of Fire-Resistant Sleeve:

Fire-resistant sleeves are installed in a manner akin to those of other protective sleeves. They offer a quick layer of protection by simply slipping them over cables, wires, or hoses.

Compliance and Certification:

Fire-resistant sleeves may need to meet particular fire safety standards and certifications depending on the use and industry regulations.

FAQs of Fire Resistant Sleeve:

1. What is the purpose of a fire-resistant sleeve?

Ans: To shield wires, cables, hoses, and other components from extreme heat, flames, sparks, and possible fire threats, use a fire-resistant sleeve. It ensures safety in crucial applications by assisting with fire containment and halting their spread.

2. A fire-resistant sleeve offers protection from flames in what ways?

Ans: Specialised materials that can withstand heat and flames are used to create fire-resistant sleeves. They offer a barrier that reduces the risk of ignition or fire propagation by preventing flames from spreading to enclosed components.

3. Which sectors frequently employ fire-resistant sleeves?

Ans: These sleeves are essential in sectors including aircraft, automotive, oil and gas, power generation, and industrial machinery where fire safety is a top concern. They are essential in reducing the hazards associated with fire.

4. Can Fire-Resistant Sleeves be customised for particular uses?

Ans: In order to fit various projects and applications, many fire-resistant sleeves can be modified in terms of size, length, and other details.

5. What is the installation process for fire-resistant sleeves?

Ans: The installation process is simple. The sleeves offer rapid protection from flames and extreme temperatures when they are slid over cables, wires, or hoses. To meet a range of diameters, multiple sizes are offered.

Premium Fire Protection for Electrical Appliances

Engineered with a blend of silicone and fiberglass, this fire resistant sleeve offers robust thermal insulation and flame-retardant properties. Its polished surface not only enhances durability but also facilitates easy cleaning and maintenance. Perfect for industries relying on electrical systems, the sleeve ensures optimal safety by shielding sensitive components from high temperatures and sparks.

Versatile and Dependable Sourcing in India

As a comprehensive supplier, manufacturer, distributor, importer, exporter, and trader based in India, we offer standardized products designed for diverse requirements. Our strict quality control measures guarantee that every fire resistant sleeve aligns with international safety and performance benchmarks, ensuring our clients receive exceptional products and service support.

FAQs of Fire Resistant Sleeve:

Q: How is the fire resistant sleeve applied in electrical appliances?

A: The sleeve is typically slipped over cables or wires in electrical appliances to protect them from heat, sparks, and potential fire hazards. Its flexibility allows for easy installation without the need for additional adhesives or fixtures.Q: What materials are used in the construction of the fire resistant sleeve?

A: Our fire resistant sleeve is crafted from high-grade silicone combined with fiberglass, offering both extraordinary heat resistance and mechanical strength for prolonged usage in challenging environments.Q: When should you use a fire resistant sleeve in electrical applications?

A: You should employ this sleeve whenever there is a risk of heat exposure or fire, such as in high-power electrical installations, industrial wiring, or sensitive circuitry where enhanced thermal protection is essential.Q: Where can the fire resistant sleeve be sourced in India?

A: The sleeve can be sourced from us, as we operate as a distributor, supplier, manufacturer, exporter, importer, and trader throughout India, providing nationwide coverage and prompt delivery.Q: What is the manufacturing process for the fire resistant sleeve?

A: The sleeve is manufactured by coating fiberglass with high-quality silicone, followed by a precision polishing treatment that ensures a smooth, durable finish. This process enhances the sleeves thermal and fire-resistant properties.Q: How does using a fire resistant sleeve benefit electrical devices?

A: Using this sleeve protects critical electrical components from fire and heat damage, extends the lifespan of wiring, and helps ensure safe operation, minimizing the risk of system failures and accidents.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese