- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Acrylic Fiberglass Sleeving

- Varnished Fiberglass Sleeve F Class

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

Fire Sleeves

20.0 INR/Meter

Product Details:

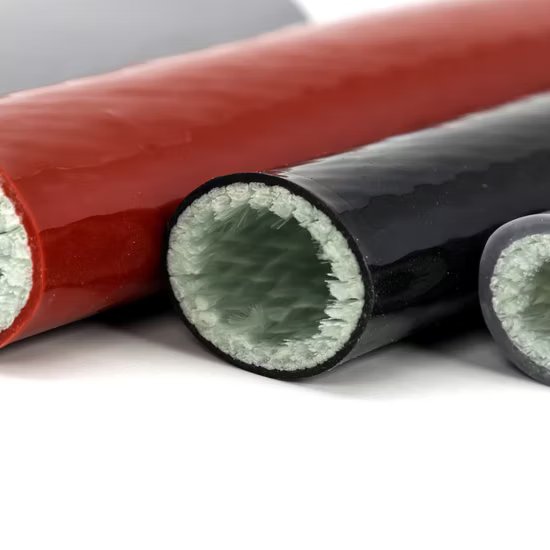

- Product Type Fire Sleeves

- Material Fiberglass

- Thickness 3 Millimeter (mm)

- Application It is used for protecting wires, cables and hoses from extreme heat, flames and sparks.

- Color Red

- Click to view more

X

Fire Sleeves Price and Quantity

- 20.0 INR/Meter

- 4 Meter

Fire Sleeves Specification

- Red

- 3 Millimeter (mm)

- Fire Sleeves

- Fiberglass

- It is used for protecting wires, cables and hoses from extreme heat, flames and sparks.

Fire Sleeves Trade Information

- 3 Days

- Australia, Central America, Middle East, South America, Western Europe, Africa, Asia, North America, Eastern Europe

- All India

Product Description

A specific protective covering known as a "fire sleeve," sometimes known as a "fire-resistant sleeve" or a "flame-retardant sleeve," is intended to act as a barrier against high temperatures, flames, sparks, and heat-related hazards. In a variety of sectors, these sleeves are frequently employed to protect wires, cables, hoses, and other components from potential fire hazards. Here is a thorough explanation of fire sleeves that highlights both their qualities and advantages:

Features of Fire Sleeves:

1. Flame Resistance: Fire sleeves are made of cutting-edge materials that naturally withstand flames. When exposed to fire or intense heat, they are able to restrict the spread of flames and resist ignition because to this characteristic.

2. Thermal Insulation: Fire sleeves provide excellent thermal insulation qualities that reduce the amount of heat that is transferred to enclosed components. This insulation helps shield cables from melting, deteriorating, or igniting nearby materials.

3. Abrasion and Impact Protection: These sleeves offer strong mechanical shielding against abrasion, impacts, and other physical stressors that cables and wires may encounter in addition to fire protection.

4. Chemical Resistance: A lot of fire sleeves are resistant to different chemicals, oils, and solvents, which improves defence against corrosive substances that could lead to cable deterioration.

5. Weather and UV Resistance: Fire sleeves are frequently made to withstand outside elements, including UV exposure, making them ideal for applications requiring both environmental toughness and fire safety.

6. Wide Temperature Range: These sleeves are made to function well in a variety of climates, providing dependable protection even under intense heat or rapid temperature changes.

7. Customization: Fire sleeves can be made to fit certain cables, hoses, or application needs because they come in a variety of sizes, lengths, and diameters.

Benefits of Fire Sleeves:

1. Fire Safety: Enhanced fire safety is the main advantage of fire sleeves. They produce a shield that keeps fires from spreading and aids in their containment, lowering the possibility of property damage and guaranteeing worker safety.

2. Protection of Components: Fire sleeves prevent against the damaging effects of heat, flames, and potential ignition sources on delicate parts, cables, and wires. Critical systems integrity and functionality are preserved because to this safeguard.

3. Adheres Industry Standard: Fire sleeves frequently adhere to industry standards and fire safety laws, ensuring that applications meet safety criteria and lowering liability worries.

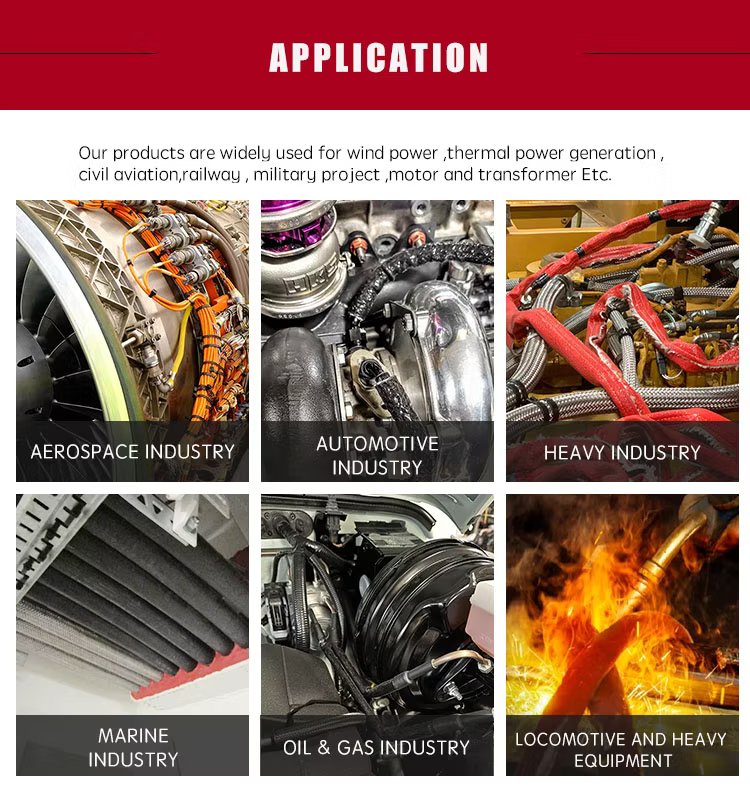

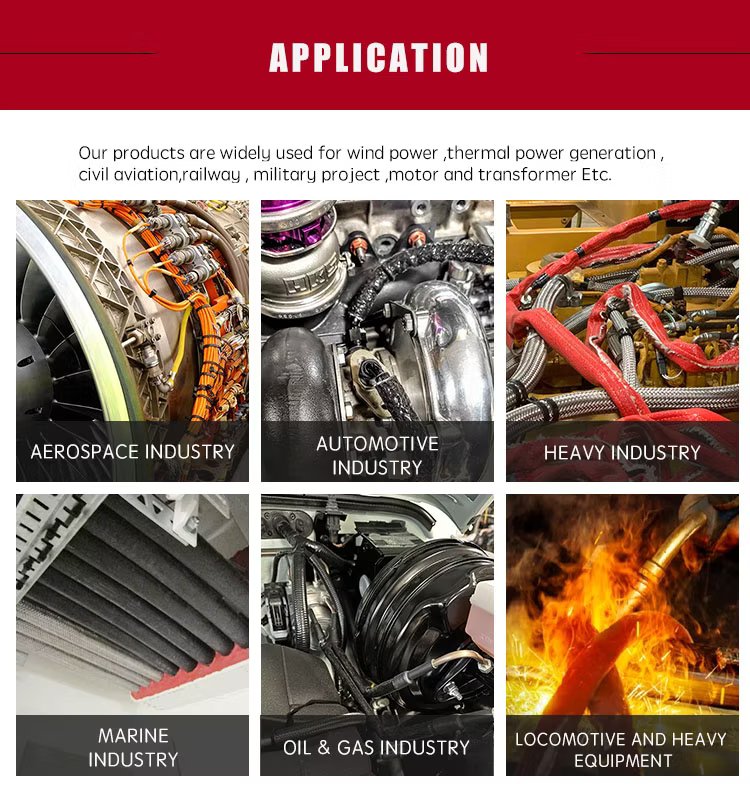

4. Reliability in Challenging and severe conditions: Fire sleeves offer dependable protection in difficult and severe conditions, such as industrial, automotive, and aerospace applications. They are resistant to fires, chemicals, weather, and UV radiation.

5. Emergency Response: By preventing the spread of fires and minimising possible damage, fire sleeves are essential in times of crisis. Their confinement capabilities aid in giving crucial response and evacuation time.

6. Longevity and Cost Savings: Fire sleeves help systems last longer by shielding cables and components from damage caused by fire and heat, which lowers maintenance costs and downtime.

FAQs of Fire Sleeves:

1. What are Fire Sleeves used for, exactly?

Ans: To create a barrier of defence against extreme heat, flames, and sparks, employ a fire sleeve. It ensures safety in a variety of applications by protecting wires, cables, hoses, and components from fire dangers.

2. How can Fire Sleeves provide resistance to flames?

Ans: Specialised materials with built-in flame resistance are used to create Fire Sleeves. They offer thermal insulation to protect enclosed components from heat-related dangers, resist ignition, and stop the spread of flames.

3. What sectors are Fire Sleeves most frequently used in?

Ans: These sleeves are used in sectors like power generation, industrial machinery, aircraft, and the automobile industry. Fire Sleeves offer essential protection in areas where fire safety is important.

4. What are the advantages of employing Fire Sleeves?

Ans: Fire sleeves increase fire safety, safeguard against heat-related component damage, guarantee regulatory compliance, provide dependability in severe settings, and help save money by increasing system longevity.

5. How are fire sleeve installations done?

Ans: Fire Sleeve installation is simple. They quickly add a layer of protection by being slipped over cables, wires, or hoses. To meet a range of diameters, multiple sizes are offered.

Superior Thermal Protection for Industrial Applications

Crafted from fiberglass, our red fire sleeves deliver exceptional resistance to heat and flames. Their primary role is safeguarding electrical wires, hydraulic lines, and cables from extreme temperatures and accidental sparks. The robust 3 mm thickness adds an extra layer of defense, making these sleeves indispensable for factories, workshops, and maintenance operations nationwide.

Versatile Sourcing Solutions Across India

As a trusted distributor, exporter, importer, manufacturer, supplier, and trader, we make high-quality fire sleeves readily available throughout India. Whether you require bulk orders or specialized sizing, our comprehensive supply chain ensures you get precisely what you need to secure your operations against fire hazards.

FAQs of Fire Sleeves:

Q: How are fire sleeves with fiberglass material installed for protecting wires and hoses?

A: Fire sleeves can be easily slipped over wires, cables, or hoses by either sliding them directly or splitting them for retrofit installation, ensuring the entire length is covered for maximum thermal protection.Q: What types of environments and applications are ideal for using these 3 mm thick fiberglass fire sleeves?

A: These fire sleeves are perfect for industrial settings such as manufacturing plants, automotive workshops, and electrical installations, where equipment is exposed to extreme heat, open flames, or intermittent sparks.Q: When should you consider using fire sleeves in your operations?

A: Fire sleeves should be employed whenever your wires, hoses, or cables are at risk of thermal damage due to high temperatures, nearby welding, or exposure to flame or sparks in daily processes.Q: Where can you source red fiberglass fire sleeves in India?

A: Our fire sleeves are available throughout India from our distribution network as we operate as a manufacturer, supplier, exporter, importer, distributor, and trader, catering to diverse industrial needs.Q: What is the process for choosing the right fire sleeve thickness for your application?

A: Selecting the correct sleeve thickness depends on the temperature exposure and the diameter of the item being protected. The 3 mm thickness provides optimal protection for most industrial applications requiring robust flame resistance.Q: How does using fire sleeves benefit the longevity of wires, cables, and hoses?

A: Fire sleeves defend components against degradation from heat and fire, thereby extending their operational life, reducing maintenance costs, and enhancing overall safety in hazardous environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese