- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Acrylic Fiberglass Sleeving

- Varnished Fiberglass Sleeve F Class

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

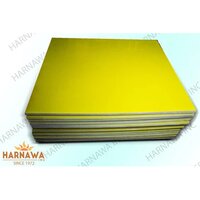

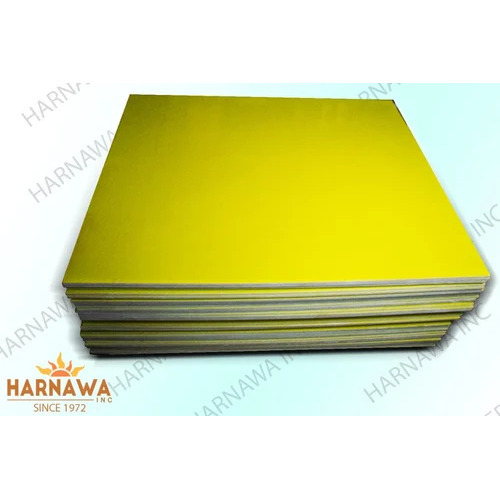

Glass Epoxy Sheets (3240 FR4 Grade)

240.0 INR/piece

Product Details:

- Thickness 0.5 mm to 100 mm (customized available) Millimeter (mm)

- Coating Type Epoxy Resin Coated Laminate

- Thermal Conductivity Low, Excellent Insulation Performance Calorie (th)/second/centimeter/C

- Density 1.8 2.0 g/cm Gram per cubic centimeter(g/cm3)

- Usage & Applications Electrical Machines, PCBs, High Voltage Insulation, Industrial Fixtures

- Temperature Up to 155 C (Class F Insulation) Celsius (oC)

- GSM N/A (not applicable for sheets)

- Click to view more

X

Glass Epoxy Sheets 3240 Price and Quantity

- 100 Kilograms

- 240.0 INR/piece

Glass Epoxy Sheets 3240 Specification

- 1020 Millimeter (mm)

- Up to 155 C (Class F Insulation) Celsius (oC)

- Electrical Machines, PCBs, High Voltage Insulation, Industrial Fixtures

- N/A (not applicable for sheets)

- 0.5 mm 100 mm (as per requirement) Millimeter (mm)

- 1.8 2.0 g/cm Gram per cubic centimeter(g/cm3)

- Glass Epoxy Sheets

- Motors, Transformers, Generators, PCB Substrates, Switchgear, Aerospace & Automotive Components

- Electrical Insulation, Structural Components, PCB Base, Industrial Applications

- Sheet / Block / Cut-to-Size

- E-Glass (Electrical Grade)

- Hot Pressed / Laminated with Epoxy Resin & Glass Fiber Cloth

- 1020mm x 2020mm (L x W)

- 0.5 mm to 100 mm (customized available) Millimeter (mm)

- 1020 2020 (Thickness as required) Millimeter (mm)

- 2.0 g/cm Kilograms (kg)

- Low, Excellent Insulation Performance Calorie (th)/second/centimeter/C

- Smooth / Polished Finish

- 2020 Millimeter (mm)

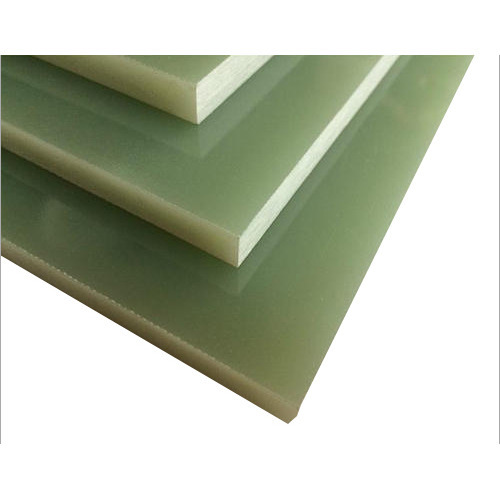

- Glass Fiber Reinforced Epoxy (FR4, 3240 Grade)

- Yellow / Green (Standard)

- Epoxy Resin Coated Laminate

Glass Epoxy Sheets 3240 Trade Information

- 3 Days

- Asia, Western Europe, Australia, Central America, South America, Eastern Europe, Africa, North America, Middle East

- All India

Product Description

Glass epoxy sheets 3240, also known as FR-4 (Flame Retardant 4), are a type of composite material commonly used in electrical and electronic applications. They are made by layering sheets of woven glass fabric impregnated with epoxy resin and then curing them under heat and pressure. The resulting material is known for its excellent electrical insulation properties, mechanical strength, and resistance to heat and fire.

Characteristics of glass epoxy sheets 3240:

1. Electrical Insulation: Glass epoxy sheets 3240 have high electrical insulation properties, making them ideal for use in electrical and electronic equipment. They can withstand high voltage and prevent electrical arcing.

2. Mechanical Strength: These sheets have good mechanical strength and can withstand mechanical stress and impact. They are rigid and can be machined or drilled for specific applications.

3. Flame Retardant: The "FR" in FR-4 stands for flame retardant. These sheets are designed to be resistant to fire and are used in applications where fire safety is a concern.

4. Temperature Resistance: Glass epoxy sheets 3240 have good thermal stability and can withstand high temperatures without deforming or losing their electrical properties.

5. Chemical Resistance: They are resistant to many chemicals, which makes them suitable for use in harsh environments where exposure to corrosive substances is a concern.

6. Low Water Absorption: These sheets have low water absorption properties, which means they do not absorb moisture easily. This feature is important in maintaining electrical insulation properties.

Applications of Glass Epoxy Sheets 3240 (FR-4) include:

1. Printed Circuit Boards (PCBs): FR-4 is one of the most common materials used for manufacturing PCBs due to its excellent electrical properties, rigidity, and flame resistance.

2. Electrical Insulation: They are used as insulating components in transformers, motors, and electrical enclosures.

3. Mechanical Components: Glass epoxy sheets 3240 are used to make various mechanical components in industries where high strength and dimensional stability are required.

4. Aerospace: In aerospace applications, these sheets are used for their lightweight yet strong characteristics.

5. Automotive: FR-4 is used in the automotive industry for making components like engine mounts and insulation panels.

6. Construction: They find applications in construction as structural and insulating materials.

7. Consumer Electronics: FR-4 is used in consumer electronics for the manufacture of rigid PCBs.

8. Medical Devices: Glass epoxy sheets are used in medical devices where electrical insulation is crucial.

FAQs:

1. What is Glass Epoxy Sheet 3240?

Ans: The thermosetting laminate material known as FR-4, also known as glass epoxy sheet 3240, is created by impregnating woven glass fabric with epoxy resin. It is a well-liked option in many industries thanks to its strong mechanical and electrical insulating qualities.

2. For what purposes does Glass Epoxy Sheet 3240 (FR-4) primarily get used?

Ans: When excellent electrical insulation and mechanical strength are required, FR-4 is utilised in a variety of applications, including as a substrate material for printed circuit boards (PCBs), electrical insulators, transformers, switchgear components, and various electronic devices.

3. Which advantages of employing Glass Epoxy Sheet 3240 (FR-4) stand out the most?

Ans: Excellent electrical insulation, flame retardancy, high-temperature resistance, mechanical strength, chemical resistance, and less water absorption are just a few advantages of FR-4. Additionally, it is affordable, adaptable, and ideal for demanding environments.

4. What equipment is needed to make or process Glass Epoxy Sheet 3240 (FR-4)?

Ans: Using common tools and methods, like CNC machining, milling, and laser cutting, FR-4 can be easily machined, cut, drilled, and moulded. This fabrication flexibility enables exact customisation to satisfy certain design needs.

5. How eco-friendly is Glass Epoxy Sheet 3240 (FR-4)?

Ans: Because it contains epoxy resin, FR-4 is not naturally eco-friendly. To address environmental issues, attempts have been undertaken to provide eco-friendly substitutes. It can support sustainability in a variety of industries when used responsibly and recycled wherever practical.

Versatile Electrical Insulation Solutions

Glass Epoxy Sheets (3240 FR4 Grade) are widely utilized for electrical insulation in high-voltage systems, PCB base materials, and industrial fixtures. With their robust structure and low thermal conductivity, these sheets offer reliable protection and performance in harsh environments, safeguarding sensitive components in motors, transformers, and other electrical machines.

Precision Engineering for Multiple Applications

Manufactured through a hot-pressed or laminated technique, these sheets maintain precise dimensions and can be customized in thickness up to 100mm. The smooth, polished surface enhances mechanical properties, making them suitable for aerospace, automotive, and specialized industrial applications. Their epoxy resin coating ensures excellent chemical and moisture resistance.

FAQs of Glass Epoxy Sheets (3240 FR4 Grade):

Q: How are Glass Epoxy Sheets (3240 FR4 Grade) manufactured?

A: These sheets are made by hot-pressing or laminating electrical-grade E-Glass fibers with epoxy resin, resulting in a smooth, polished finish and robust mechanical strength. The process ensures excellent insulation and dimensional stability.Q: What are the primary uses of 3240 FR4 Grade Glass Epoxy Sheets?

A: They serve as insulation components in motors, transformers, generators, PCB substrates, switchgear, and are also used in aerospace and automotive industries due to their durability and electrical performance.Q: When should I choose a custom thickness for my application?

A: Custom thicknesses (from 0.5mm to 100mm) are recommended when standard sizes do not meet specific mechanical or insulation requirements in your application. Manufacturers and suppliers in India provide tailored solutions to match project needs.Q: Where can Glass Epoxy Sheets be used in industrial settings?

A: These sheets are utilized in electrical machines, high-voltage insulation systems, industrial fixtures, and as PCB base materials. Their versatility also extends to sectors like aerospace and automotive engineering.Q: What benefits does FR4 (3240) grade provide over other materials?

A: FR4 (3240) grade offers superior electrical insulation, thermal stability up to 155C, and chemical resistance. Its high strength-to-weight ratio ensures reliable performance in demanding environments.Q: How does the surface treatment enhance the sheets properties?

A: The smooth, polished surface treatment improves mechanical strength and electrical insulation, while providing resistance against moisture, chemicals, and wear, extending the components lifespan.Q: What is the standard color and why does it matter?

A: The standard color for 3240 FR4 Glass Epoxy Sheets is yellow or green. While color does not affect performance, it aids in easy identification and enhances aesthetic appeal in end applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese