- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Electrical Insulating Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Laminated Fleece Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

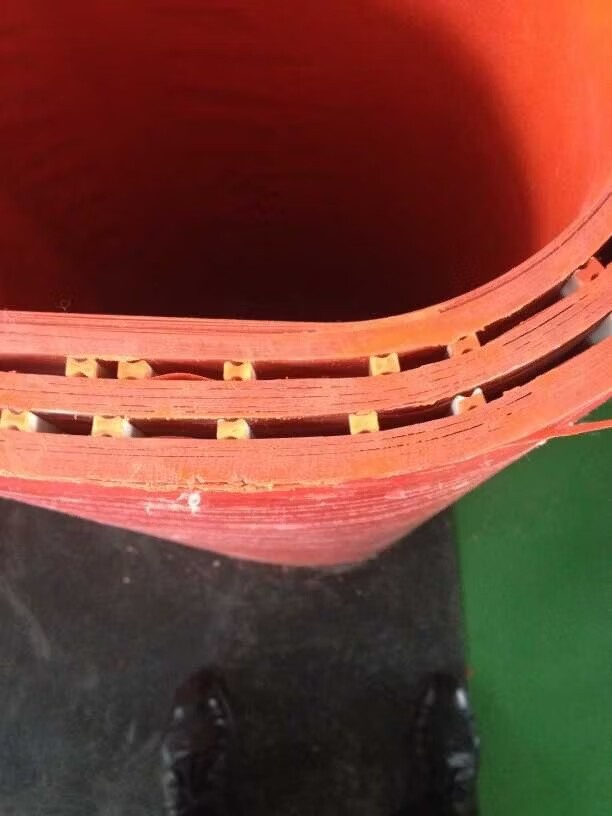

Epoxy Dog Bone

22.0 INR/unit

Product Details:

- Thermal Conductivity ~0.25 0.35 Watt/Meter/K (w/(m.k)

- Coating Type Uncoated

- Glass Type Woven / Unidirectional Fiberglass

- Usage & Applications Motors, generators, transformers, switchgear

- Density ~1.8 2.0 g/cm Gram per cubic centimeter(g/cm3)

- Temperature Class F (155 C) / Class H (180 C) Celsius (oC)

- Shape Dog Bone Profile

- Click to view more

X

Epoxy Dog Bone Price and Quantity

- 1 Kilograms

- 22.0 INR/unit

Epoxy Dog Bone Specification

- Dog Bone Profile

- 8 25 mm (dog bone slot design) Millimeter (mm)

- Class F (155 C) / Class H (180 C) Celsius (oC)

- 3 10 mm standard (custom available) Millimeter (mm)

- Standard 1000 mm 20 mm 8 mm (customizable) Millimeter (mm)

- Standard

- High-voltage insulation & slot separation

- Pultrusion of epoxy resin reinforced with fiberglass

- White/Brown / Natural (custom on request)

- Epoxy Dog Bone Profile

- ~1.8 2.0 g/cm Gram per cubic centimeter(g/cm3)

- Electrical insulation in motors, generators, and transformers

- Woven / Unidirectional Fiberglass

- As per thickness Millimeter (mm)

- Motors, generators, transformers, switchgear

- 1000 mm 2000 mm (standard) Millimeter (mm)

- As per size & length Grams (g)

- Epoxy Resin + Fiberglass Reinforcement

- Uncoated

- ~0.25 0.35 Watt/Meter/K (w/(m.k)

- Smooth finish

Epoxy Dog Bone Trade Information

- 1000 Kilograms Per Month

- 3 Days

- Africa, Australia, Central America, Western Europe, Asia, Eastern Europe, North America, South America, Middle East

- All India

Product Description

Epoxy Dog Bone High Strength Electrical Insulation Material

Epoxy Dog Bone is a specially designed insulation profile made from epoxy resin reinforced with fiberglass, offering excellent mechanical strength, electrical insulation, and thermal stability. These profiles are commonly used in motors, generators, transformers, and other high-voltage electrical equipment where reliable insulation and dimensional stability are critical.

The dog bone shape provides superior slot insulation and phase separation, ensuring safe operation under high electrical stress and temperature conditions. With high dielectric strength, flame resistance, and moisture resistance, epoxy dog bones are widely trusted by motor manufacturers, transformer OEMs, and electrical equipment industries.

At Harnawa Insulations., we manufacture and supply epoxy dog bone profiles in various sizes, lengths, and thicknesses to meet customer-specific requirements. All products comply with Class F (155C) and Class H (180C) insulation standards and are tested for durability and reliability.

Applications of Epoxy Dog Bone

Slot Insulation in motors and generators

Phase Insulation in high-voltage windings

Reinforcement in transformers and switchgear

Electrical & Thermal Insulation for OEM equipment

Custom Profiles for motor and transformer manufacturers

Key Benefits

-

High dielectric strength for electrical insulation

-

Excellent thermal stability (up to 180C)

-

Superior mechanical strength and dimensional accuracy

-

Resistant to chemicals, oils, and moisture

-

Available in multiple sizes and custom designs

Reliable Electrical Insulation for Demanding Applications

Epoxy Dog Bones are engineered to provide dependable insulation and slot separation for motors, generators, and transformers. The composition of epoxy resin with fiberglass delivers mechanical strength and excellent resistance to high temperatures, making them suitable for extended operational life in electrical equipment.

Customizable Design to Meet Your Specifications

With standard lengths from 1000 mm to 2000 mm and thicknesses ranging from 3 mm to 10 mm, these dog bone profiles can be tailored to unique application requirements. Color options include white, brown, natural, or custom shades, ensuring versatility for diverse installation needs in the power sector.

FAQs of Epoxy Dog Bone:

Q: How is the Epoxy Dog Bone used in electrical equipment?

A: The Epoxy Dog Bone serves as an insulating spacer or slot separator in motors, generators, transformers, and switchgear, preventing electrical short circuits and ensuring reliable operation under high voltage.Q: What benefits does epoxy resin with fiberglass reinforcement provide?

A: The combination of epoxy resin and fiberglass reinforcement delivers superior electrical insulation, mechanical strength, and resistance to heat, ensuring long-term durability and safety in electrical and thermal environments.Q: When should I consider a custom size or color for the Epoxy Dog Bone?

A: Custom sizes and colors are recommended for specialized applications where standard dimensions or colors may not fit the slot design or aesthetic requirements of your equipment. Customization ensures the optimal fit and performance.Q: Where are these Epoxy Dog Bones commonly installed?

A: These components are typically found in high-voltage electrical equipment such as motors, generators, transformers, and switchgear, where reliable insulation and slot separation are critical.Q: What is the standard manufacturing process for these profiles?

A: Epoxy Dog Bones are manufactured using a pultrusion technique, where epoxy resin is reinforced with either woven or unidirectional fiberglass to achieve precise shapes and consistent mechanical properties.Q: How does surface treatment affect the performance of the Epoxy Dog Bone?

A: A smooth finish on the surface minimizes electrical tracking and contamination, further enhancing the dielectric performance and longevity of the insulation in electrical assemblies.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese