- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- Fire Resistant Sleeve

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Acrylic Fiberglass Sleeving

- Varnished Fiberglass Sleeve F Class

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Eurotherm Laminated Nomex Paper NPN

- Laminated Fleece Paper

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

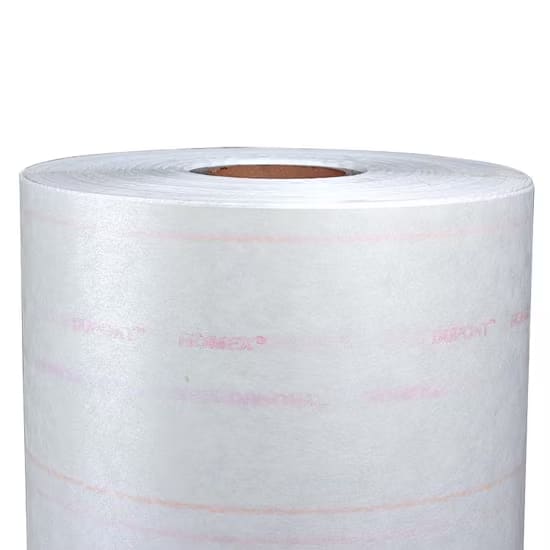

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

Laminated Nomex

190.0 INR/Kilograms

Product Details:

- Paper Type Specialty Paper

- Coating Uncoated

- Size Standard

- Thickness Varies as per GSM & lamination type (customizable) Millimeter (mm)

- Weight Varies as per GSM & lamination type (customizable) GSM (gm/2)

- Moisture Low (controlled for electrical insulation use)

- Feature Fire Proof

- Click to view more

X

Laminated Nomex Price and Quantity

- 190.0 INR/Kilograms

- 1 Kilograms

Laminated Nomex Specification

- Standard

- Excellent mechanical durability

- Uncoated

- White / Off-White (standard Nomex shade)

- Digital Printing

- Specialty Paper

- High dimensional stability, resistant to shrinkage

- Fire Proof

- 0.9 1.2 Gram per cubic centimeter(g/cm3)

- Varies as per GSM & lamination type (customizable) GSM (gm/2)

- 910 mm (standard, customizable on request) Millimeter (mm)

- Standard

- Low (controlled for electrical insulation use)

- High-Performance Aramid Insulation Material

- Varies as per GSM & lamination type (customizable) Millimeter (mm)

Laminated Nomex Trade Information

- 1000 Kilograms Per Month

- 3 Days

Product Description

Laminated Nomex refers to a composite material that combines layers of Nomex with other materials through a lamination process. Nomex is a high-performance synthetic material made from aramid fibers, and it is known for its excellent heat resistance, flame resistance, and electrical insulation properties. The material is often used in various industries, including aerospace, automotive, electrical, and firefighting, where protection against extreme heat and fire is critical.

The lamination process involves bonding layers of Nomex with other materials like adhesive films, fiberglass, or other composites to create a composite material with specific properties. Laminating Nomex with other materials can enhance its mechanical strength, durability, or add other functional characteristics.

Some common applications of laminated Nomex include:

1. Electrical Insulation: Laminated Nomex is widely used for electrical insulation in transformers, motors, and other electrical equipment due to its excellent electrical insulating properties.

2. Thermal Insulation: In aerospace and automotive applications, laminated Nomex can provide thermal insulation to protect sensitive components from high temperatures.

3. Firefighter Gear: Firefighters often wear gear made from laminated Nomex to protect themselves from extreme heat and flames.

4. Aircraft Interiors: Laminated Nomex composites are used in aircraft interiors for their fire resistance properties.

5. Gaskets and Seals: In industrial applications, laminated Nomex gaskets and seals are used in environments where heat and fire resistance are required.

6. Flexible Laminates: Flexible laminated Nomex can be used in flexible printed circuit boards (PCBs) or other applications where a combination of electrical insulation and flexibility is needed.

Laminated Nomex FAQ:

1. What is Nomex?

Ans: Nomex is a high-performance synthetic material made from aramid fibers. It is known for its exceptional heat resistance, flame resistance, and electrical insulation properties.

2. What is Laminated Nomex?

Ans: Laminated Nomex is a composite material that combines layers of Nomex with other materials through a lamination process. This process enhances its mechanical properties or adds specific functionalities.

3. What are the advantages of using Laminated Nomex?

Ans: Laminated Nomex offers several benefits, including excellent heat resistance, flame resistance, electrical insulation, mechanical strength, and durability. It is used in applications where protection against extreme heat, flames, or electrical hazards is necessary.

4. Where is Laminated Nomex commonly used?

Ans: Laminated Nomex finds applications in various industries, such as aerospace, automotive, electrical, firefighting, and more. It is used in electrical insulation, thermal insulation, firefighter gear, aircraft interiors, gaskets, and flexible laminates, among others.

5. Can Laminated Nomex be customized for specific applications?

Ans: Yes, laminated Nomex can be customized by adjusting the number of Nomex layers, the type of adhesive or composite materials used, and the overall thickness of the laminate. This customization allows it to meet specific performance requirements.

6. Is Laminated Nomex fire-resistant?

Ans: Yes, Nomex itself is inherently flame-resistant, and when laminated with other materials, it retains its fire-resistant properties. This makes it suitable for applications where protection against flames and high temperatures is crucial.

7. How does Laminated Nomex perform as an electrical insulator?

Ans: Laminated Nomex is an excellent electrical insulator, making it ideal for use in transformers, motors, flexible printed circuit boards (PCBs), and other electrical equipment. It helps prevent electrical arcing and shorts.

8. What are some safety-related applications of Laminated Nomex?

Ans: Firefighters often use gear made from laminated Nomex to protect themselves from extreme heat and flames. Additionally, it is used in aircraft interiors and industrial settings where fire resistance and heat protection are required.

9. Is Laminated Nomex recyclable or environmentally friendly?

Ans: Nomex is a thermoplastic material, and its environmental impact can vary depending on specific formulations and recycling facilities. Some efforts have been made to recycle Nomex-based materials, but the availability of recycling options may vary by location.

10. Are there any limitations or considerations when using Laminated Nomex?

Ans: While Laminated Nomex offers numerous advantages, it may not be suitable for applications where exposure to certain chemicals or high abrasion is a concern. Users should carefully evaluate its compatibility with their specific requirements.

Exceptional Fire Proofing and Mechanical Durability

Laminated Nomex stands out for its fireproof properties and robust mechanical durability, suitable for demanding environments. Its high density (0.91.2 g/cm) ensures enhanced protection and longevity. The material is engineered to resist bursting and shrinkage, making it dependable for both electrical insulation and specialty paper needs.

Customizable Sizes and Thickness for Diverse Applications

With a standard width of 910 mm, Laminated Nomex can be tailored in thickness and weight (GSM) according to client specifications. This flexibility supports a wide range of industrial requirements, from precision insulation to specialized manufacturing processes in India and abroad.

FAQs of Laminated Nomex:

Q: How is the thickness of Laminated Nomex determined?

A: The thickness of Laminated Nomex is customizable and varies depending on the selected GSM and lamination type, allowing it to meet specific project requirements for insulation or mechanical performance.Q: What benefits does Laminated Nomex offer for electrical insulation applications?

A: Laminated Nomex provides low moisture absorption, fireproofing, high dimensional stability, and excellent mechanical durability, making it an optimal choice for electrical insulation tasks that demand reliable protection and longevity.Q: Where can I use Laminated Nomex specialty paper?

A: This material is widely used in electrical insulation, fire-safe packaging, specialty manufacturing, and any application requiring high performance, dimensional stability, and mechanical strength.Q: What is the process for customizing the size and GSM of Laminated Nomex?

A: Custom sizes, thickness, and GSM can be specified during the ordering process. The manufacturer will tailor the product according to client requirements for lamination type, width, and other parameters.Q: Can Laminated Nomex be printed on, and what printing methods are compatible?

A: Yes, Laminated Nomex supports digital printing, offering versatile solutions for labeling or branding while maintaining its insulation and durability features.Q: When is it recommended to choose uncoated Laminated Nomex?

A: Uncoated Laminated Nomex is ideal for cases requiring excellent fireproof qualities, low moisture content, and direct compatibility with digital printing methods without additional processing.Q: What makes Laminated Nomex resistant to shrinkage and bursting?

A: The high-performance aramid fiber composition and precise manufacturing process ensure exceptional dimensional stability and mechanical strength, reducing shrinkage and enhancing durability against bursting forces.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese