- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Electrical Insulating Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Laminated Fleece Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

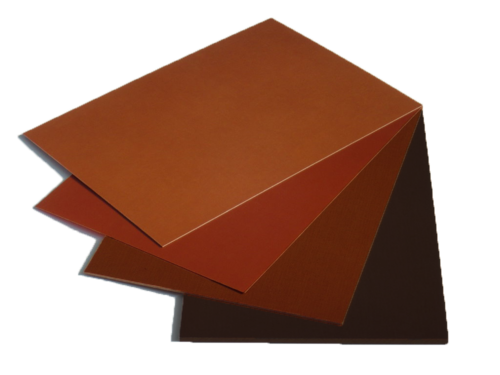

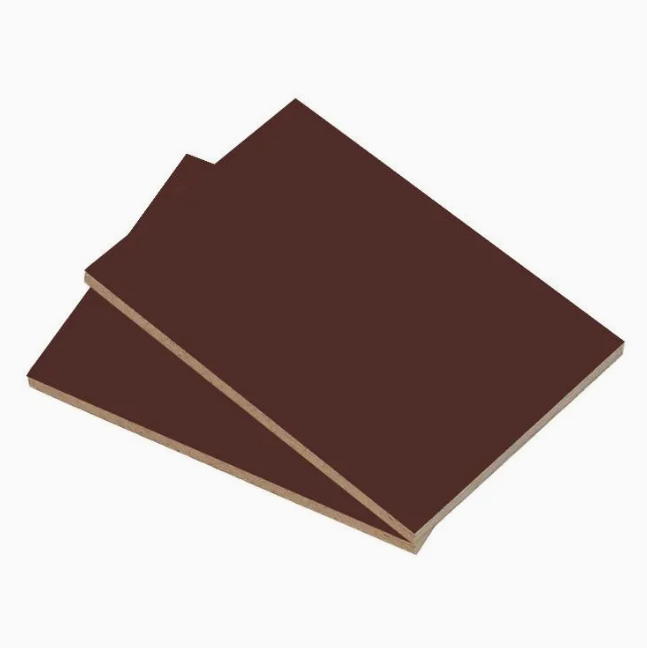

Bakelite Sheet Fabric

20.0 INR/Meter

Product Details:

- Size Standard

- Material Bakelite

- Thickness 6 Millimeter (mm)

- Warranty 1 year

- Color Brown

- Display Type Nil

- Features Good Quality

- Click to view more

X

Bakelite Sheet Fabric Price and Quantity

- 1 Kilograms

- 20.0 INR/Meter

Bakelite Sheet Fabric Specification

- Nil

- Good Quality

- 1 year

- 6 Millimeter (mm)

- Bakelite

- Brown

- Standard

Bakelite Sheet Fabric Trade Information

- 1000 Kilograms Per Day

- 3 Days

- Africa, Asia, Australia, Central America, Middle East, Eastern Europe, Western Europe, South America, North America

- All India

Product Description

A type of material created from Bakelite, a historically significant and pioneering synthetic plastic, is known as bakelite sheet fabric. One of the first synthetic plastics ever made, bakelite was produced by Belgian chemist Leo Baekeland in the early 20th century. Its heat-resistant, insulating, and moldable qualities significantly contributed to the revolutionization of sectors including electrical, automotive, and consumer goods.

Bakelite sheets are made by heating and applying pressure to layers of cloth or paper that have been impregnated with Bakelite resin. The end product has good electrical insulating qualities and is rigid and long-lasting. Solid sheets, laminates, and composite materials are just a few of the variations of bakelite sheet fabric that are available. Electrical insulation components like switchboards, connections, and insulating panels were frequently made with it.

Bakelite Sheet Fabrics Features:

1. High heat resistance makes bakelite sheet fabric ideal for applications involving high temperatures, such as industrial machinery and electrical equipment.

2. This substance possesses remarkable electrical insulation qualities, which make it perfect for use in electrical and electronic components to avoid short circuits and guarantee security.

3. Bakelite sheet fabric demonstrates good dimensional stability and mechanical strength. It can tolerate light impacts and mechanical pressures.

4. Bakelites ability to be moulded into many shapes during the curing process enables the development of elaborate designs and complex shapes.

5. It exhibits resistance to a wide range of chemicals and solvents, which adds to its robustness and appropriateness for industrial applications.

6. Bakelite was one of the first fully synthetic plastics, which was historically significant since it represented a breakthrough in manufacturing and material science.

7. Bakelite sheet fabrics ability to be dyed and moulded into distinctive patterns and colours made it popular for ornamental applications. Both the Art Deco movement and vintage consumer goods benefited from it.

Bakelite Sheet Fabric Specifications:

1. Grade: P1 / P2 / P3 / F1 / F2 / F3

2. Finishing Type: Smooth / Glossy

3. Shape: Rectangular

4. Density: 2.2 kg/cm2

5. Material: Hylam and Bakelite

6. Color: Brown

7. Heat Resistance: Yes

8. Weather Resistance: Yes

9. Wear Resistance: Yes

FAQ:

1. What is the purpose of Bakelite sheet fabric?

Ans: In applications where both heat resistance and electrical insulation are crucial, bakelite sheet cloth is frequently used for electrical insulation. It is used to make parts for electrical equipment such as switchboards, insulating panels, connections, and more.

2. Is there still a market for Bakelite sheet fabric?

Ans: In many industrial applications, Bakelite sheet fabric was once widely utilised, but with to improvements in plastics and composites, it has been mostly supplanted by more contemporary materials. For aesthetic, vintage, or historical restoration projects, it might still be in demand.

3. Why is Bakelite sheet cloth a good choice for electrical applications?

Ans: The fabric made of bakelite has exceptional mechanical strength, heat resistance, and electrical insulating qualities. It is a dependable option for electrical components that demand endurance and high temperature resistance since it can endure extreme temperatures and prevent electrical short circuits.

4. Can Bakelite sheet cloth be shaped differently?

Ans: Yes, during the curing phase, Bakelite sheet fabric can be moulded into many shapes. It is adaptable for various applications due to its moldability, which enables the fabrication of complicated shapes and components with precise geometry.

5. Can I still get Bakelite sheet fabric?

Ans: While the original Bakelite sheet cloth may be hard to find, there are several contemporary materials with comparable qualities on the market right now. These materials incorporate contemporary manufacturing methods and safety regulations while attempting to mimic Bakelites characteristics of heat resistance and electrical insulation.

Superior Material Quality

Each Bakelite Sheet Fabric is constructed using top-grade Bakelite material, ensuring enhanced mechanical strength and efficient electrical insulation. Thanks to its robust design and precise thickness, it delivers reliability across demanding applications.

Versatile Industrial Applications

With a thickness of 6 millimeters and standard sizing, this sheet fabric is widely utilized in Indian industries such as automotive, electronics, and machinery. Its your trusted solution for insulation, support, and protection needs.

FAQs of Bakelite Sheet Fabric:

Q: How is the Bakelite Sheet Fabric manufactured and distributed in India?

A: The Bakelite Sheet Fabric is produced using advanced fabrication techniques to achieve uniform thickness and quality. As a manufacturer, exporter, importer, supplier, trader, and distributor in India, the company ensures nationwide availability through a reliable supply network.Q: What are the main uses of the Bakelite Sheet Fabric?

A: This Bakelite sheet is primarily employed for insulation in electrical devices, panel boards, and mechanical supports, owing to its excellent insulating properties and sturdy build. Its versatility allows for use in a variety of industrial and engineering contexts.Q: When should I consider using Bakelite Sheet Fabric in my projects?

A: You should choose Bakelite Sheet Fabric when high strength, heat resistance, and good electrical insulation are required. It is particularly beneficial for applications involving electrical safeguards, industrial machinery, and structural support.Q: Where can I find reliable Bakelite Sheet Fabric suppliers in India?

A: In India, the Bakelite Sheet Fabric is readily available through established distributors, importers, manufacturers, and traders who specialize in industrial materials. Our company ensures consistent nationwide supply and support.Q: What is the process for installing Bakelite Sheet Fabric?

A: Installation typically involves cutting the sheet to the desired size, fastening it securely, and integrating it into the system where insulation or mechanical strength is needed. The materials consistent thickness allows for precise fitting and easy handling.Q: How does the 1-year warranty benefit customers?

A: The one-year warranty on Bakelite Sheet Fabric assures customers of dependable quality and product performance. It offers protection against manufacturing defects, ensuring peace of mind and confidence for buyers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese