- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Acrylic Fiberglass Sleeving

- Varnished Fiberglass Sleeve F Class

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Electrical Insulating Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Laminated Fleece Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

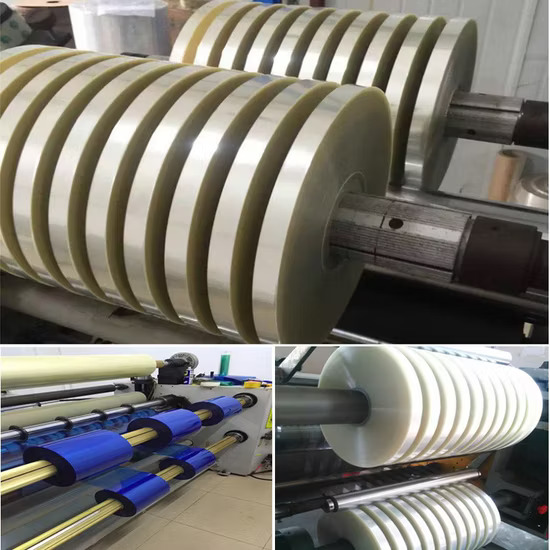

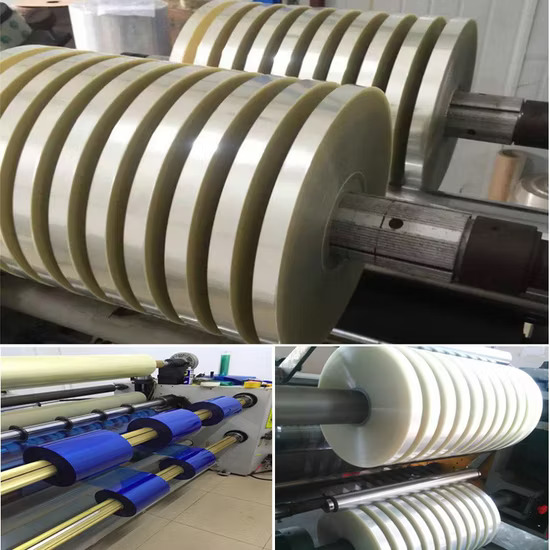

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

Garware White Polyester Film

50.0 INR/Kilograms

Product Details:

- Surface Treatment Smooth, Milky White finish

- Feature Excellent electrical insulation properties Good thermal stability High mechanical strength Resistant to moisture and chemicals Uniform milky white appearance for easy identification Flexible and easy to process (slitting, cutting, wrapping)

- Coating Type Uncoated / Heat-sealable (available on request)

- Thermal Conductivity 0.15 W/mK (approx.) Watt/Meter/K (w/(m.k)

- Density 1.39 g/cm (approx.) Gram per cubic centimeter(g/cm3)

- Layer Single-layer film, can be laminated

- Product Type Electrical Insulation Film

- Click to view more

X

Garware White Polyester Film Price And Quantity

- 50.0 INR/Kilograms

- 1 Kilograms

Garware White Polyester Film Product Specifications

- Electrical Insulation Film

- Polyester Film

- 0.15 W/mK (approx.) Watt/Meter/K (w/(m.k)

- Suitable for low to medium voltage insulation applications Volt (V)

- Not applicable (insulation material)

- 1.39 g/cm (approx.) Gram per cubic centimeter(g/cm3)

- Uncoated / Heat-sealable (available on request)

- White / Milky White

- -70 C to +150 C Celsius (oC)

- 150 220 MPa Megapascals (MPa )

- Standard manufacturer warranty against defects in material & workmanship

- Excellent electrical insulation properties Good thermal stability High mechanical strength Resistant to moisture and chemicals Uniform milky white appearance for easy identification Flexible and easy to process (slitting, cutting, wrapping)

- Smooth, Milky White finish

- 180 C

- Single-layer film, can be laminated

- Electrical insulation for motors, transformers, and cables Slot liners and phase separators in electric machines Flexible laminates with other insulation substrates Packaging and protective covering in electrical industry

- 6 10 kV (depending on thickness) Volt (V)

- Excellent electrical insulation properties Good thermal stability High mechanical strength Resistant to moisture and chemicals Uniform milky white appearance for easy identification Flexible and easy to process (slitting, cutting, wrapping)

- Electrical insulation for motors, transformers, and cables Slot liners and phase separators in electric machines Flexible laminates with other insulation substrates Packaging and protective covering in electrical industry

- Up to 1000 mm (standard rolls, slitting available) Millimeter (mm)

- 50 350 Microns (customizable as per requirement) Micrometers (um)

- Not applicable (insulation material) Volt (v)

Garware White Polyester Film Trade Information

- 3 Days

Product Description

| Production name | Heat Resistant High Temperature Polyimide film/electrical insulation Polyimide Film/Electrical Polyester Film (PET)/Milky White Polyester Film (Motor Film) |

| Material | Polyimide film/polyimide film/polyimide film heater/polyimide film tape/polyimide films with sticky layerpolyimide film pi film |

| Color | Milky white, transparent |

| Usage | widely widely used in high temperature masking protection in electronics industry |

| Feature | 1. Frequency conversion power supply in electronic industry. also use as a perfect heat resistance tape on 3d printing, powder coating, etcs 2. Protection of Printed Circuit Boards during wave soldering 3. Insulation on Transformers, Motors and Coils, Fiber Optics Cables, Solar Panels. 4. High temperature masking 5. Excellent electrical insulation 6. Outstanding dimensional stability 7. Great thermal resistance 8. Leaves no defective gum when tear off 9. Discs are on a clear, slit back liner for easy removal |

| Advantage | 1.Factory supplier: mylar film polyimide film heat resistant paper PI film 2.Competitive price:Factory direct sales, professional production, quality assurance, 3.Perfect service:Delivery in time,and any question will be replied in 24 hours |

Sample provide |

1. We send sample A4 paper size for free 2. Customer shall bear the freight charges 3. Sample and freight charge just a show of your sincerity 4. All sample related cost shall be returned after first deal 5. It is workable to most of our clients Thanks for cooperation |

Features:Good Quality polyamide PI Film sheet die cut for All Thickness And Marketkapton polyimide film is anElectrical insulationmaterial with outstanding thermal, mechanical, chemical and electrical properties.3Mhas been used successfully in field applications where the environmental temperatures were as low as -269C and as high as 400C.It can be easily fabricated by a wide variety of techniques, including die cutting, punching and thermoforming.Itis available in 5 different thicknesses from 23 micron to 125 micron and in several different grades type HN being the most popular.HN film can be laminated, metallized, punched, formed or adhesive coated.

It is highly recommended for applications requiring an all-polyimide film with an excellent balance of properties over a wide range of temperatures.

INTRODUCTION:

The Polyimide tape is used Polyimide film as carrier and coated with silicone adhesive single side.With excellent Acid resistance, anti-solvent, anti-radiation and easy peel off.Widely used in printed circuit board (PCB), SMT tin stove, Lithium battery,electronics industry transformers, motors, coils, capacitors and variable frequency power supply etc...

FEATURES:

Polyimide sheetThe polyimide film was used as the base material, and the imported silicone pressure sensitive adhesive was usedHigh and lowtemperature resistance, acid and alkali resistance, solvent resistance, electrical insulation, radiation protection and otherproperties.It is suitable for shielding electronic circuit board with wave soldering, insulating goldfinger and high-grade electricappliances, insulating motor, and fixing anode and cathode lugs of lithium batteryPolyimide tape use polyimide film as a substrate, coated on high-performance silicone pressure-sensitive adhesive.

DATA SHEET:

DATA SHEET:

|

Technical Data

|

||||

|

No.

|

Index Name

|

Unit

|

Index

|

Result

|

|

1

|

Tensile Strength(MD and CD)

Nominal Thickness: <15 15100 100190 >190 |

Mpa

|

150

150 140 110 |

155

152 147 115 |

|

2

|

Elongation(MD and CD)

Nominal Thickness: <15 1550 >50350 |

%

|

60

80 100 |

68

86 107 |

|

3

|

Shrinkage(MD and CD)

Nominal Thickness: <15 15190 >190 |

%

|

3.5

3.0 2.0 |

3.9

3.5 2.8 |

|

4

|

Volume Resistance Rate

|

m

|

1.01014

|

1.01015

|

|

5

|

Relative Permittivity

50Hz 1kHz |

|

2.93.4

/ |

2.93.4

|

|

6

|

Dielectric dissipation

50Hz 1kHz |

|

5.010-3

|

5.010-2

|

|

7

|

Density

|

kg/m3

|

139010

|

1395

|

|

8

|

Melting Point

|

C

|

256

|

262

|

|

9

|

Surface Resistivity

|

|

1.01013

|

1.01014

|

|

10

|

Electrolytic etching

Ocular Estimate The tensile strength of plain conductor |

% |

A1

2 |

A1

1.7 |

|

11

|

Dimensional Stability at High temperatures

In Tension Under Pressure |

C

|

200

200 |

202

205 |

|

12

|

Long-term heat resistanceTransparent insulation 6020/6021 polyester pet film

|

|

105

|

130

|

Superior Electrical Insulation Performance

Garware White Polyester Film provides a high level of electrical insulation, making it the preferred choice for motors, transformers, cables, and slot liners. Its breakdown voltage ranges from 6 to 10 kV depending on film thickness, ensuring dependable protection for low to medium voltage applications. The films IP20 rating signifies basic insulation, suitable for a wide variety of equipment indoors.

Flexible Customization for Every Industry Need

Available in thicknesses ranging from 50 to 350 microns and widths up to 1000 mm, this polyester film can be customized through slitting or cutting. Whether you require standard rolls or specialty laminate substrates, the films flexibility and uniform, milky white finish support efficient identification and handling during processing.

Durability Across Challenging Environments

Highly resistant to moisture, chemicals, and thermal stress, Garware White Polyester Film operates across a wide temperature range (-70C to +150C) and offers high mechanical strength (tensile: 150220 MPa). Its robust performance ensures long-lasting insulation and protection, minimizing maintenance downtime and safeguarding electrical components.

FAQs of Garware White Polyester Film:

Q: How is Garware White Polyester Film used in electrical insulation?

A: Garware White Polyester Film serves as slot liners and phase separators in motors and transformers, as well as insulation for cables. Its high dielectric strength and mechanical durability make it ideal for protecting electrical components against breakdown and environmental factors.Q: What customization options are available for thickness and width?

A: The film is offered in thicknesses from 50 to 350 microns and widths up to 1000 mm (standard rolls), with slitting and cutting services available to meet specific project requirements.Q: When should I choose heat-sealable versus uncoated variants?

A: Select heat-sealable types if you require the film to be bonded with other materials or during lamination in manufacturing processes. The uncoated version is suitable for general insulation and protective purposes where heat-bonding is not required.Q: Where is this polyester film typically applied within the electrical industry?

A: It is commonly used in slot liners and phase separators for electric machines, lamination with other insulation substrates, and as packing or protective covering for electrical components, particularly in motors, transformers, and cable insulation.Q: What are the main benefits of using this film for electrical insulation?

A: Key benefits include excellent electrical insulation, robust thermal stability, superior tensile strength, resistance to moisture and chemicals, and a uniform milky white appearance for easy identification and processing.Q: How does the film withstand harsh thermal and mechanical conditions?

A: Designed to perform in temperatures from -70C to +150C and withstand up to 180C temporarily, its high mechanical strength (150220 MPa) and chemical resistance provide longevity and stable performance even in demanding electrical environments.Q: What warranty and quality assurances are provided?

A: The product comes with a standard manufacturer warranty against defects in material and workmanship, ensuring reliable quality for all supplied films.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese