- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Acrylic Fiberglass Sleeving

- Varnished Fiberglass Sleeve F Class

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Electrical Insulating Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Laminated Fleece Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

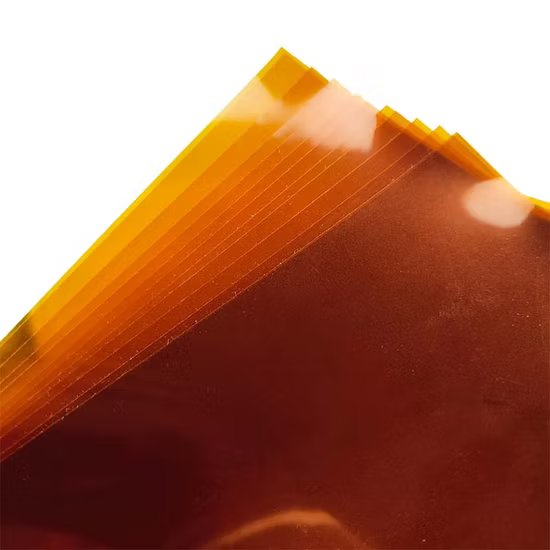

Polyamide Film

50.0 INR/Kilograms

Product Details:

- Feature High tensile strength, abrasion resistance, good electrical insulation, excellent barrier to gas & oil, flexible at low temperatures.

- Product Type Electrical & Industrial Insulation Film

- Rated Voltage 120 180 kV/mm Volt (V)

- Width Customizable (typically 250 mm 1500 mm) Millimeter (mm)

- Thickness 12 m 125 m (standard range) Micrometers (um)

- Application Electrical insulation in motors, transformers, cables; packaging industry; laminates for insulation papers; automotive and aerospace thermal protection.

- Usage & Applications Motor & transformer insulation, flexible laminates, cable wraps, electrical & electronic insulation, barrier films for industrial packaging.

- Click to view more

X

Polyamide Film Price And Quantity

- 1 Kilograms

- 50.0 INR/Kilograms

Polyamide Film Product Specifications

- -60 C to +150 C (continuous use) Celsius (oC)

- Motor & transformer insulation, flexible laminates, cable wraps, electrical & electronic insulation, barrier films for industrial packaging.

- Electrical insulation in motors, transformers, cables; packaging industry; laminates for insulation papers; automotive and aerospace thermal protection.

- Polyamide (Nylon-based thermoplastic film)

- High tensile strength, abrasion resistance, good electrical insulation, excellent barrier to gas & oil, flexible at low temperatures.

- Customizable (typically 250 mm 1500 mm) Millimeter (mm)

- High tensile strength, abrasion resistance, good electrical insulation, excellent barrier to gas & oil, flexible at low temperatures.

- Electrical & Industrial Insulation Film

- 12 m 125 m (standard range) Micrometers (um)

- Natural, Transparent, or Milky White

- 120 180 kV/mm Volt (V)

Polyamide Film Trade Information

- Mumbai, India

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID), Paypal, Cash Against Delivery (CAD)

- 1000 Kilograms Per Day

- 2 Days

- No

- Free samples are available

- Packed in cones/bobbins, carton boxes, or pallets

- Asia, Australia, Central America, Middle East, North America, South America, Eastern Europe, Western Europe, Africa

- All India

- UL certified, ISO-certified product quality

Product Description

Polyimide Fluorine Composite Film Polyimide Film

Polymide film is a kind of special plastic film, flat and smooth, no crease,no particular air bubble and no pinhole, with excellent mechanical properties,

dielectric properties, long-term working temperature-195 degree to 280 degree,widely used in sophisticated products in appliance, statellite navigation, digital product,electric motors, computer, mobile phone and so on, such as the base dielectrics in flexibleprinted circuits (FPC), tape automated bonding (TAB), pressure sensitive tape (PST),and insulation for electric motor(Insulation).

It has excellent electrical insulation properties, mechanical properties, excellent temperature resistance, resistance to Radiation, chemical stability and flame retardancy and etc.

it iswidely used for wire insulation wrapping and coil insulation binding of largeindustrial motors, traction motors, and generators.

| Indicator name | Unit | Index value | ||||||

| Nominal thickness | um | 25 | 40 | 50 | 75 | 100 | 125 | |

| Thickness deviation | um | 4 | 4 | 7 | 8 | 7 | 11 | |

| Iensile strength (vertical / lateral) | um | 165 | 165 | 165 | 165 | 165 | 165 | |

| Elongation at break(verticalateral) | % | 40 | 50 | 50 | 50 | 50 | 50 | |

| AC electrical strength(48Hz-62Hz) | V/um | 235 | 195 | 175 | 120 | |||

| Slitting width | range | mm | Allowable devation | |||||

| <26 | 0.4 | |||||||

| 26102 | 0.8 | |||||||

| >102 | 1.6 | |||||||

| density | kg/m3 | 142510 | ||||||

| Melting point | ---- | Not melting | ||||||

| Relativepermittivity 23C | 50Hz | --- | 3.50.4 | |||||

| 1KHz | 3.40.4 | |||||||

| Dielectric loss factor 23 C, 50 Hzor 1 Hz | 4.0x10-3 | |||||||

| Volume resistivity | .m | 1.0x1010 | ||||||

| Surface resistivity | 1.0x1014 | |||||||

| Water absorption (wet 24h) | % | 4.0 | ||||||

Versatile Electrical & Industrial Performance

Polyamide Film excels in demanding environments due to its impressive electrical insulation and mechanical durability. This film is highly suitable for wrapping conductors in motors and transformers, serving as a primary or secondary insulation layer. Its high performance extends well into the packaging and aerospace fields, offering both thermal and chemical protection.

Custom Sizing and Application Flexibility

With customizable widths (250 mm to 1500 mm) and a wide standard thickness range (12125 micrometers), Polyamide Film can be tailored to precise specifications. This adaptability ensures compatibility across various industries, from industrial electrical manufacturing to protective barrier films in packaging and transportation sectors.

FAQs of Polyamide Film:

Q: How is Polyamide Film typically used in electrical applications?

A: Polyamide Film is widely employed for electrical insulation in motors, transformers, and cables due to its high rated voltage and excellent dielectric properties. It acts as a durable, reliable barrier against electrical discharge and external contaminants.Q: What are the key benefits of using Polyamide Film over other insulating films?

A: This film provides superior tensile strength, abrasion resistance, and flexibility at low temperatures. It also exhibits excellent barrier properties against oil and gases, making it a preferred material for applications needing both mechanical and electrical reliability.Q: When should I consider choosing Polyamide Film for my project?

A: Polyamide Film is ideal when your application requires continuous use in extreme temperatures (60C to +150C), high electrical insulation, mechanical durability, or robust chemical resistance, such as in automotive, aerospace, and high-voltage electrical industries.Q: Where can Polyamide Film be sourced in India?

A: As a distributor, exporter, importer, manufacturer, supplier, and trader, Polyamide Film is widely available across India from specialized industrial material suppliers serving the electrical, packaging, and engineering sectors.Q: What is the process of customizing Polyamide Film for specific requirements?

A: You can request Polyamide Film in customized widths (typically 250 mm1500 mm) and thicknesses (12 m125 m). Suppliers assess your applications needssuch as voltage, temperature resistance, and barrier requirementsbefore tailoring the films size and type accordingly.Q: What typical industries benefit from Polyamide Film usage?

A: Industries such as electrical manufacturing, automotive, aerospace, and industrial packaging gain from Polyamide Film due to its insulating properties, flexibility, and chemical resilience, which ensure product performance and operational safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese