- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- Fire Resistant Sleeve

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Polyurethane Fiberglass Sleeve

- Fire Sleeves

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Eurotherm Laminated Nomex Paper NPN

- Laminated Fleece Paper

- Electrical Insulating Paper

- Saturated Fleece Paper

- Laminated Aramid Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Pure Aramid (Nomex) Paper

- Electrical Insulation Papers and Laminates

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

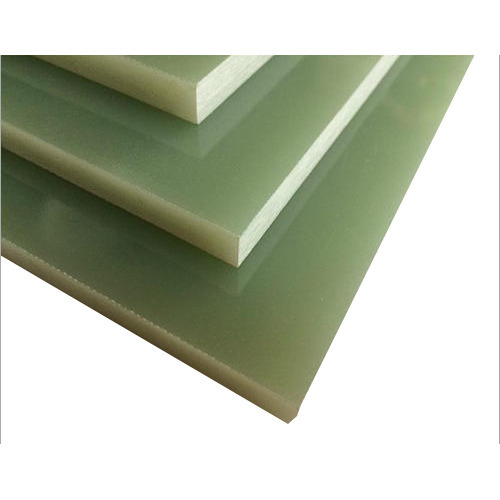

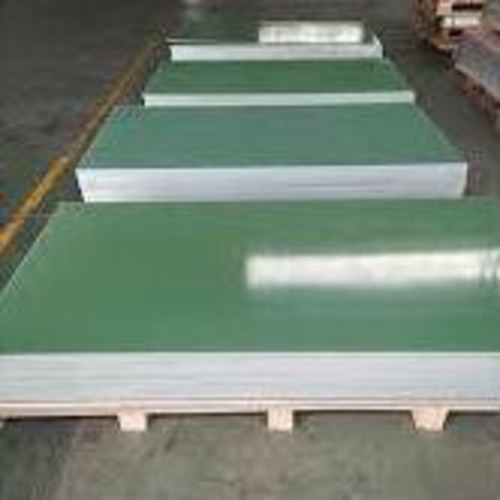

Glass Epoxy Sheet G10

295.0 INR/Kilograms

Product Details:

- Density 1.8 2.0 g/cm Gram per cubic centimeter(g/cm3)

- Thermal Conductivity Low, Excellent Insulation Properties Calorie (IT)/second/centimeter/C

- Coating Type Epoxy Resin Laminated

- Thickness 0.5 mm 100 mm (custom cut-to-size available) Millimeter (mm)

- Temperature G10: Up to 130 C (Class B Insulation) G11: Up to 180 C (Class H Insulation) Celsius (oC)

- Glass Type E-Glass (Electrical Grade)

- GSM Not Applicable

- Click to view more

X

Glass Epoxy Sheet G10 Price And Quantity

- 270.00 - 450.00 INR/Kilograms

- 1 Kilograms

- 295.0 INR/Kilograms

Glass Epoxy Sheet G10 Product Specifications

- Smooth / Polished Finish

- 0.5-10 Millimeter (mm)

- Not Applicable

- Glass Epoxy Sheet (G10 / G11 Grade)

- E-Glass (Electrical Grade)

- Standard & Custom (e.g., 1020 2020 mm)

- 202 Centimeter (cm)

- Electrical Machines, Aerospace Components, Mechanical Fixtures, PCB Backing, High-Voltage Insulation

- Hot Pressed / Laminated with Epoxy Resin & Fiberglass Cloth

- Motors, Generators, Transformers, Switchgear, Aerospace, Automotive, PCB Supports

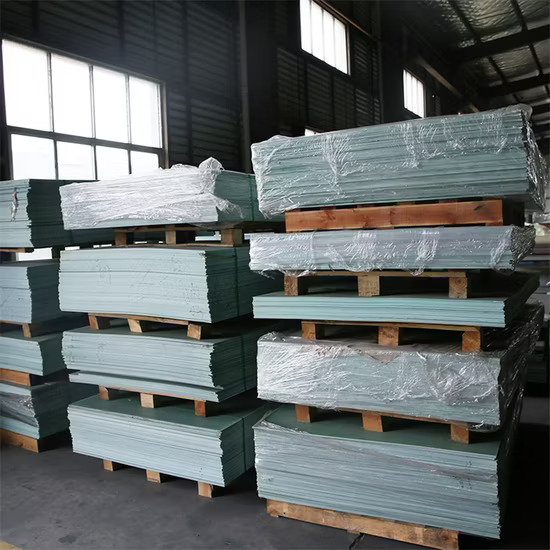

- Sheet / Block / Cut-to-Size

- Electrical Insulation, Mechanical Components, PCB Base, Aerospace & Automotive Parts

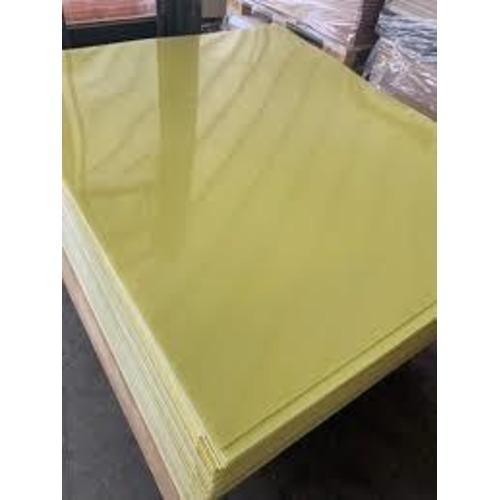

- Green, Yellow

- Varies as per thickness & size (approx. 2.0 g/cm density) Grams (g)

- 102 cm 202 cm (thickness as per order) Centimeter (cm)

- 102 Centimeter (cm)

- Low, Excellent Insulation Properties Calorie (IT)/second/centimeter/C

- 1.8 2.0 g/cm Gram per cubic centimeter(g/cm3)

- G10: Up to 130 C (Class B Insulation) G11: Up to 180 C (Class H Insulation) Celsius (oC)

- 0.5 mm 100 mm (custom cut-to-size available) Millimeter (mm)

- Epoxy Resin Laminated

- Glass Fiber Reinforced Epoxy (G10 / G11 Grade)

Glass Epoxy Sheet G10 Trade Information

- Mumbai / Bhiwandi

- Telegraphic Transfer (T/T), Paypal, Cash in Advance (CID), Cash Advance (CA), Cheque

- 10000 Kilograms Per Month

- 3 Days

- No

- Free samples are available

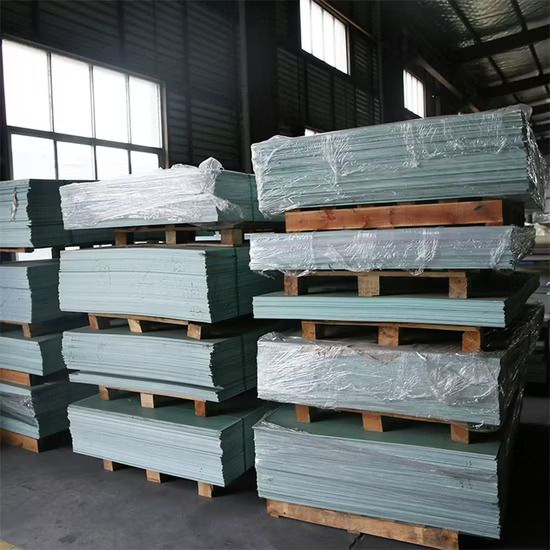

- Waterproof wrapping in wooden pallets.

- Asia, Australia, North America, Eastern Europe, Middle East, Africa, South America, Western Europe, Central America

- All India

- CE & RoHS

Product Description

High-performance thermosetting laminate materials known as grade G10 and grade G11, respectively, are Glass Epoxy Sheets. Due to their superior mechanical and electrical insulation qualities, they are extensively used in a variety of industries, including electronics, aerospace, and electrical applications.

Epoxy Fiberglass Sheet Specifications:

1. Length And Width Tolerance: +-25 mm

2. Available Thickness: 0.15 mm - 100 mm

3. Insulation Class: H & F

4. Size: 610 mm X 1020 mm, 1020 mm X 1020 mm, 1030 mm X 1230 mm

5. Color available: Light Green, Natural

6. Thickness Variation: Upto 5 mm +- 0.10 mm, Above 5 mm +- 0.50 m

Characteristics of Glass Epoxy Sheet G10 / G11:

1. Composition of the Material: Woven glass fabric impregnated with epoxy resin makes up G10 and G11. The composition of the glass fabrics in the two classes is what distinguishes them most from one another. While G11 makes use of a high-temperature glass fabric, G10 uses a regular glass fabric.

2. Insulation against electricity: G10 and G11 both have excellent electrical insulating qualities. They are suitable for use in applications where electrical isolation and dependability are essential due to their high dielectric strength.

3. Resistance to Temperature: G10 can withstand high temperatures well, usually up to 130 - 150 deg C (26 - 302 deg F). G11, on the other hand, can often endure temperatures of 180 - 200 Deg Centigrade. Due to the differential in temperature resistance, G11 is better suited for applications requiring greater heat resistance.

4. Strength mechanical: Both grades show good dimensional stability and mechanical strength. With minimal distortion or breaking, they can tolerate mechanical stress, vibration, and physical impact.

5. Resistance to Chemicals: G10 and G11 are suited for use in locations where exposure to corrosive substances may occur since they are resistant to various chemicals, including acids and solvents.

6. Flame-retardant: They are made with self-extinguishing capabilities and are flame retardant by design. As a result, they inhibit combustion and wont aid in the spread of fire, improving safety in a variety of applications.

7. Reduced Water Absorption: Due to their minimal water absorption, both grades can withstand prolonged exposure to moisture without losing their mechanical or electrical performance.

8. Flexibility: G10 and G11 are adaptable materials that have a variety of uses, including as electrical insulators, structural elements, bushings, gaskets, and other parts in the aerospace and maritime industries.

9. Manufacturability: Using common equipment and methods, they are easily machined, cut, drilled, and shaped, enabling exact customization to satisfy particular design needs.

10. Environmental Points to Consider: Due to the epoxy resin component, G10 and G11 are not naturally eco-friendly, but correct handling and disposal are crucial to reducing their negative effects on the environment. Recycling and proper garbage disposal are crucial factors to take into account.

FAQs:

1. What are G10 and G11 Glass Epoxy Sheets?

Ans: High-performance thermosetting laminate materials called Glass Epoxy Sheets G10 and G11 are created by impregnating woven glass fabric with epoxy resin. They are recognised for their remarkable mechanical and electrical insulating qualities.

2. What is the main distinction between the G10 and the G11?

Ans: Their glass fabric composition is the main distinction. While G11 makes use of a high-temperature glass fabric, G10 uses a regular glass fabric. G11 is better suited for applications requiring stronger temperature resistance as a result of this distinction.

3. Where are G10 and G11 most frequently utilised?

Ans: Numerous industries, including electronics, aircraft, and electrical engineering, use G10 and G11. They are utilised for a variety of products where electrical insulation and mechanical strength are crucial, including electrical insulators, structural elements, circuit boards, bushings, and gaskets.

4. What ranges of temperatures are G10 and G11 resistant to?

Ans: G11 can endure greater temperatures, often up to 180-200 deg centigrade, while G10 normally has a temperature resistance of up to 130-150 deg C (266-302 deg F). Depending on the precise temperature requirements of particular applications, engineers decide between the two categories.

5. What is the fabrication or machining process for G10 and G11?

Ans: Using common tools and methods like CNC machining, milling, and laser cutting, G10 and G11 can be easily machined, cut, drilled, and moulded. This adaptability enables exact customization to satisfy the special design demands of various applications.

Exceptional Electrical and Mechanical Performance

G10/G11 Glass Epoxy Sheets excel in providing robust electrical insulation and mechanical durability, making them suitable for demanding environments found in transformers, switchgear, and motors. Their tight tolerance control and low thermal conductivity add to their reliability in high-voltage and high-temperature settings, ensuring consistent, safe performance over time.

Versatile Applications and Customization Options

These sheets cater to multiple industries; from PCB bases and mechanical fixtures to aerospace and automotive components. With options for custom cut-to-size dimensions, they can be manufactured as sheets, blocks, or precise components, tailored to specific technical requirements or applications. This versatility allows seamless integration into diverse projects and assemblies.

FAQs of Glass Epoxy Sheet G10 / G11:

Q: How are G10 and G11 glass epoxy sheets manufactured?

A: G10 and G11 sheets are produced using a hot pressing technique where epoxy resin and E-glass fiberglass cloth are laminated together under heat and pressure. This process ensures a dense, uniform, and dimensionally stable sheet with superior insulation and mechanical properties.Q: What benefits do G10/G11 sheets offer for electrical and mechanical applications?

A: These sheets provide high dielectric strength, excellent insulation, low thermal conductivity, and robust mechanical strength. Their heat resistance (up to 130C for G10 and 180C for G11) and polished finish make them ideal for demanding uses in PCB supports, transformers, motors, and aerospace parts.Q: Where can glass epoxy sheets G10/G11 be used?

A: Glass epoxy sheet G10/G11 finds utility in a broad range of applications, including transformers, electrical motors, circuit boards, shipbuilding, aerospace, defense, automotive sectors, and as base supports in PCBs and electrical components.Q: When should I choose G10 vs G11 grade sheets?

A: G10 sheets are recommended for standard electrical insulation and mechanical support up to 130C, suitable for general electronics or electrical machinery. G11, with a higher thermal resistance of up to 180C, is ideal for applications involving higher operating temperatures, such as aerospace and industrial systems.Q: What are the available sizes and customization options for these sheets?

A: Standard dimensions include 1020 x 2020 mm, with thicknesses from 0.5 mm to 10 mm. Custom cut-to-size options are available to accommodate project-specific requirements. Sheets can be supplied in different shapessheet, block, or as per requested specification.Q: How should glass epoxy sheets be handled and processed?

A: Sheets should be cut and machined using carbide-tipped tools for precision. Their smooth, polished finish minimizes dust generation, promoting safety, and the sturdy surface can be easily cleaned, making them straightforward to integrate and maintain in assemblies.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese