- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Polyester Expandable Braided Sleeves

- Insulation Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Polyurethane Fiberglass Sleeve

- Fire Sleeves

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Pure Aramid (Nomex) Paper

- Electrical Insulation Papers and Laminates

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

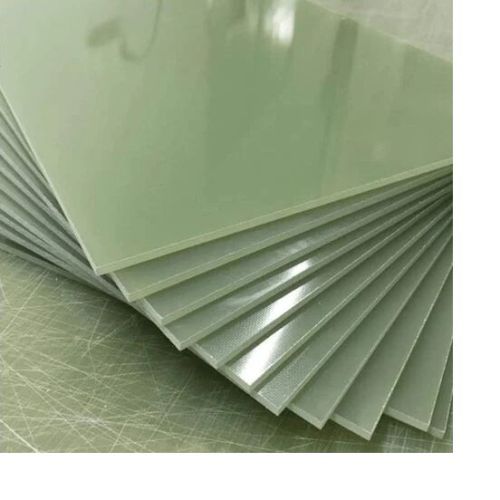

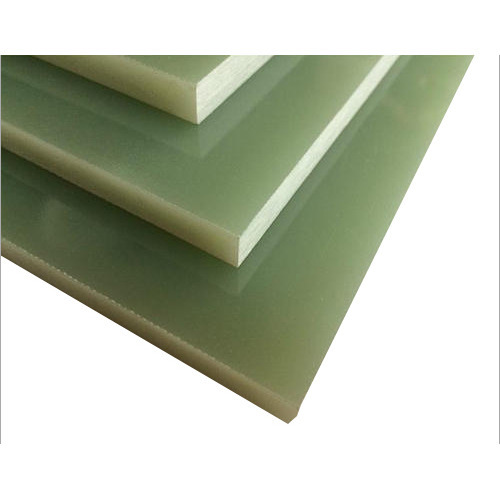

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

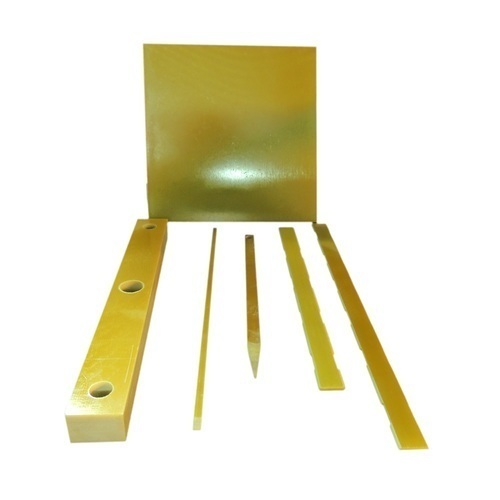

Plastic Wedges

10.0 INR/Meter

Product Details:

- Usage Industrial

- Size Standard

- Material Plastic

- Surface Treatment Galvanized

- Color Golden

- Click to view more

X

Plastic Wedges Price and Quantity

- 1 Kilograms

- 10.0 INR/Meter

Plastic Wedges Specification

- Standard

- Plastic

- Galvanized

- Industrial

- Golden

Plastic Wedges Trade Information

- 1000 Kilograms Per Month

- 3 Days

- Asia, Western Europe, Middle East, North America, Australia, Central America, Eastern Europe, South America, Africa

- All India

Product Description

Plastic wedges are multipurpose instruments with a wedge shape that are created from various types of plastic. They are used in a variety of sectors and do-it-yourself tasks.

Characteristics of plastic wedges:

1. Depending on the needs of the application, plastic wedges can be constructed from a variety of plastics, including high-density polyethylene (HDPE), polypropylene, nylon, and others.

2. They often have a wedge form with a tapered profile, which allows for fine control and adjustability.

3. Plastic wedges are portable and simple to use, which lessens user fatigue from extended use.

4. Plastic wedges are suitable for fragile materials or finishes since they are non-marring, which means they wont scratch or harm the surfaces they come into touch with.

5. Depending on the type of plastic, they may be resistant to different chemicals, acids, and solvents, which qualifies them for work involving chemicals.

6. The majority of plastic wedges are moisture- and water-resistant, making them appropriate for damp areas.

7. Electrical insulation is a feature of several plastics used to make these wedges, making them suitable for use in electrical or electronic applications.

8. Depending on the particular type of plastic, plastic wedges may tolerate a variety of temperatures.

Advantages of plastic wedges:

1. Plastic wedges have many uses, including in DIY, plumbing, automotive, woodworking, and construction tasks. They can be utilised for activities including spreading, aligning, levelling, and shimming.

2. They are appropriate for use on delicate materials like wood, glass, or finished surfaces because they are non-marring, which means they wont leave marks or harm surfaces.

3. Plastic wedges are frequently less expensive than their wooden or metal counterparts, making them a cost-effective option for numerous applications.

4. Plastic wedges are lightweight and have an ergonomic design that making them simple to handle and manoeuvre, which helps prevent user fatigue during extended use.

5. Plastic wedges are low-maintenance and have a longer service life than wooden wedges, which may need replacement or periodic maintenance due to wear or rot.

6. Plastic wedges generate less noise when struck when compared to metal wedges, making them appropriate for noise-sensitive environments.

7. Plastic wedges are excellent for jobs in settings where exposure to these elements is widespread due to their resistance to chemicals and moisture.

8. Plastic wedges are frequently used for electrical jobs because of their insulating qualities, which, when used properly, lower the risk of electrical accidents.

FAQs:

1. What exactly are plastic wedges and how do you utilise them?

Ans: A variety of plastic materials are used to create wedge-shaped instruments known as plastic wedges. They are employed in a variety of professions and do-it-yourself projects for operations like shimming, levelling, spreading, and aligning. They are especially helpful for applications where surface protection is crucial due to their non-marring qualities.

2. What kinds of plastic are typically used to create plastic wedges?

Ans: High-density polyethylene (HDPE), polypropylene, nylon, and other robust plastic materials can all be used to make plastic wedges. The plastic to use depends on the demands of the application and the desired qualities of the wedge.

3. Can plastic wedges be used in load-bearing and heavy-duty applications?

Ans: In general, mild to medium-duty applications are suited for plastic wedges. They may not be the greatest option for heavy-duty or load-bearing applications, where metal or wooden wedges may be more suitable, despite their benefits such surface protection and non-marring characteristics.

4. Are plastic wedges suitable for use in corrosive or moist environments?

Ans: Yes, many plastic wedges can endure exposure to moisture and are water-resistant. These wedges are made of plastic, some of which are resistant to various acids, solvents, and chemicals, making them appropriate for usage in wet or chemical settings.

5. Can you safely use plastic wedges for electrical work?

Ans: When plastic wedges possess electrical insulation capabilities, they might be a secure option for electrical work. By inhibiting conductivity, they assist in lowering the possibility of electrical accidents. But its essential to make sure the particular plastic wedge being used is appropriate for electrical duties and complies with safety requirements and laws.

Robust Construction for Heavy-Duty Applications

Our golden Plastic Wedges are built to withstand industrial environments. The galvanized surface ensures exceptional resistance to rust and general wear, while the sturdy plastic material maintains its shape under pressure, guaranteeing reliable performance for frequent or prolonged use.

Versatility and Wide Availability

We cater to a broad clientele as manufacturers, suppliers, and traders. Our Plastic Wedges are readily available for bulk orders and can be sourced throughout India. Whether youre operating a factory or running a construction business, our products are accessible and adaptable to diverse industrial needs.

FAQs of Plastic Wedges:

Q: How are plastic wedges with galvanized surfaces typically used in industrial settings?

A: These plastic wedges are primarily utilized for leveling, aligning, and securing machinery or structural components. The galvanized treatment provides added resistance to corrosive industrial environments, making them suitable for both indoor and outdoor applications.Q: What are the main benefits of using golden plastic wedges for industrial purposes?

A: The key advantages include excellent corrosion resistance, lightweight yet durable construction, and their ability to withstand significant pressure without deforming. Their standard size ensures compatibility with most industrial fixtures and equipment.Q: When should I replace my plastic wedges in industrial applications?

A: You should inspect wedges periodically and replace them if you notice excessive wear, deformation, or loss of structural integrity. Regular maintenance helps maintain workplace safety and optimal equipment alignment.Q: Where can I purchase these golden plastic wedges in India?

A: Our golden plastic wedges are available across India through our distribution channels. As a major manufacturer, supplier, trader, and exporter, we fulfill orders for businesses of all sizes and can arrange prompt delivery nationwide.Q: What is the process involved in manufacturing plastic wedges with a galvanized finish?

A: The manufacturing process involves molding high-grade plastic into standard wedge shapes, followed by the application of a galvanization technique. This surface treatment enhances the wedges durability and shields it from environmental wear.Q: How should I use industrial plastic wedges safely and effectively?

A: To use these wedges safely, firmly position them between surfaces or machinery needing alignment or levelling. Always ensure the area is stable and that the wedges are correctly placed to prevent slipping or movement during use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese