- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Acrylic Fiberglass Sleeving

- Varnished Fiberglass Sleeve F Class

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Electrical Insulating Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Laminated Fleece Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

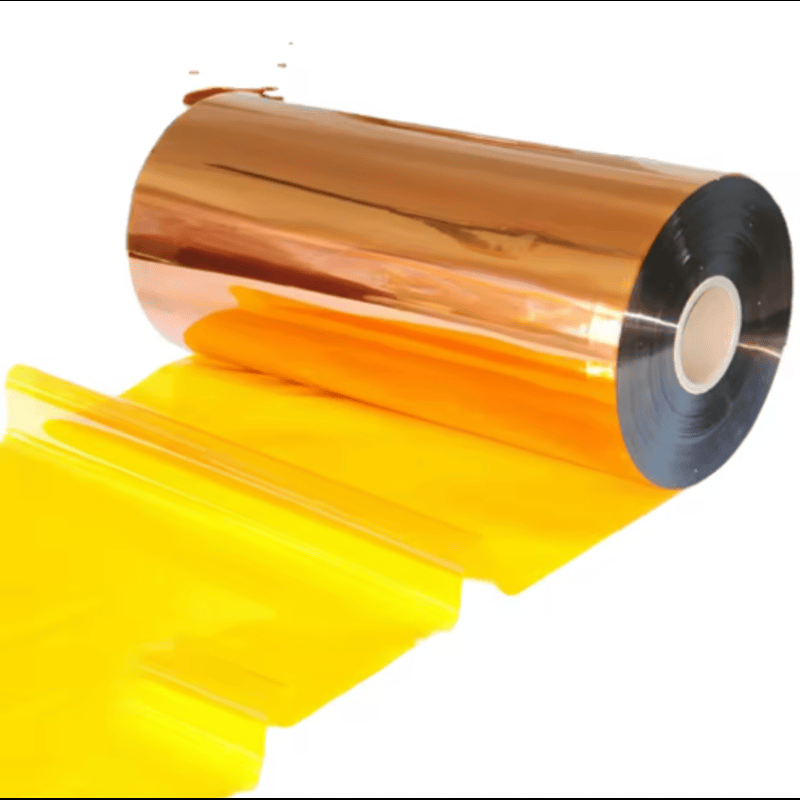

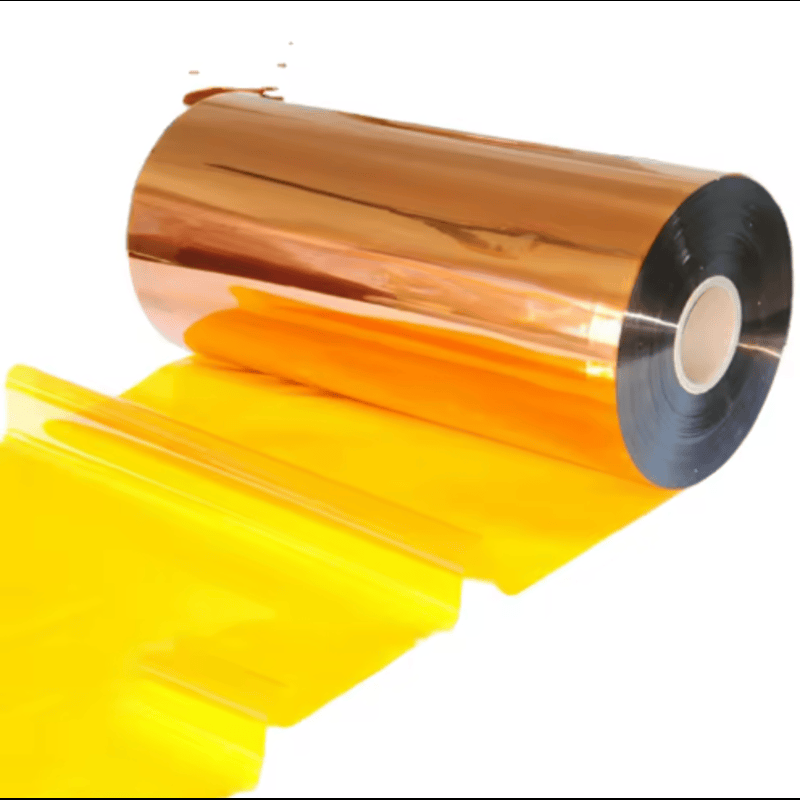

FEP Polyamide Film

20.0 INR

Product Details:

- Density 1.42 g/cm (approx.) Gram per cubic centimeter(g/cm3)

- Coating Type FEP coating on one or both sides (as required)

- Feature Excellent dielectric and thermal insulation properties High heat resistance up to 200 C continuous use Chemical, moisture, and radiation resistant Non-stick surface due to FEP coating Superior flexibility and mechanical strength Suitable for heat-sealing and lamination

- Installation Guideline Store in clean, dry conditions; process with controlled heat sealing if required

- Surface Treatment Smooth, FEP-coated glossy surface

- Layer Single layer polyimide with FEP coating

- Thermal Conductivity 0.12 0.15 W/mK Watt/Meter/K (w/(m.k)

- Click to view more

X

FEP Polyamide Film Price And Quantity

- 20.0 INR

- 1 Kilograms

FEP Polyamide Film Product Specifications

- Amber / Golden Transparent

- Single layer polyimide with FEP coating

- 0.12 0.15 W/mK Watt/Meter/K (w/(m.k)

- 12 125 Microns (customizable) Micrometers (um)

- Store in clean, dry conditions; process with controlled heat sealing if required

- 260 C (short-term use)

- Smooth, FEP-coated glossy surface

- Not applicable (insulation material)

- Wire and cable insulation (aerospace, automotive, electronics) Flexible printed circuits (FPC) Transformer and motor insulation High-temperature adhesive tapes Coils, sensors, and heater insulation

- Not applicable (insulation material) Volt (v)

- 5 12 kV (depending on thickness) Volt (V)

- -200 C to +200 C continuous Celsius (oC)

- Industrial insulation for 50/60 Hz and high-frequency applications Hertz (HZ)

- High-Temperature Electrical Insulation Film

- Up to 1000 mm (slitting available) Millimeter (mm)

- 150 220 MPa Megapascals (MPa )

- Not applicable (insulation material)

- 0.12 0.15 W/mK Watt/Meter/K (w/(m.k)

- 1.42 g/cm (approx.) Gram per cubic centimeter(g/cm3)

- Polyimide Film with FEP (Fluorinated Ethylene Propylene) Coating

- Suitable for low to high-voltage insulation depending on thickness Volt (V)

- Excellent dielectric and thermal insulation properties High heat resistance up to 200 C continuous use Chemical, moisture, and radiation resistant Non-stick surface due to FEP coating Superior flexibility and mechanical strength Suitable for heat-sealing and lamination

- FEP coating on one or both sides (as required)

- Standard

- Wire & Cable Insulation, Transformers, Motors, Flexible Printed Circuits, Aerospace & Automotive Electronics

- Excellent dielectric and thermal insulation properties High heat resistance up to 200 C continuous use Chemical, moisture, and radiation resistant Non-stick surface due to FEP coating Superior flexibility and mechanical strength Suitable for heat-sealing and lamination

FEP Polyamide Film Trade Information

- Mumbai, India

- Paypal, Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C)

- 5000 Kilograms Per Day

- 2 Days

- No

- Free samples are available

- Packaging & Delivery Package Size 30.00cm * 20.00cm * 10.00cm Package Gross Weight 1.200kg

- Asia, North America, South America, Eastern Europe, Western Europe, Australia, Central America, Middle East, Africa

- All India

- UL, CE, RoHS, ISO 9001:2015, REACH Compliant, Electrical Research and Development Association

Product Description

FEP Polyimide Film

FEP (Fluorinated Ethylene Propylene) coated Polyimide Film is a high-performance insulation material widely used in electrical, electronic, and aerospace applications. By combining the superior thermal stability of polyimide with the chemical resistance and non-stick properties of FEP, this film delivers excellent performance in demanding environments.

The film offers high dielectric strength, outstanding flexibility, and resistance to heat, moisture, and chemicals. It is commonly used for wire and cable insulation, flexible printed circuits, coil and transformer wrapping, and other high-temperature insulation requirements.

Key Benefits

-

Exceptional electrical insulation with high breakdown voltage

-

Heat-resistant, operating reliably up to 200C continuous use

-

Non-stick and chemically resistant surface due to FEP coating

-

Excellent mechanical strength and dimensional stability

-

Flexible and easy to process for wrapping, laminating, or fabricating

Applications

-

Wire and cable insulation for aerospace, automotive, and electronics

-

Flexible printed circuits (FPCs) and specialty laminates

-

Transformer and motor insulation wrapping

-

High-temperature tapes and industrial adhesives

-

Insulation for coils, heaters, and sensors

If you are seeking a durable, high-temperature insulation material with superior chemical resistance, FEP Polyimide Film is a trusted solution for advanced industrial and electrical applications.

Superior Insulation and Thermal Endurance

Designed for both low and high-voltage uses, FEP Polyamide Film provides excellent dielectric properties and handles continuous temperatures up to 200C. Its robust construction ensures reliable insulationeven in rigorous industrial environmentsmaking it ideal for applications ranging from wire and cable insulation to transformer and motor protection.

Reliable Resistance and Durability

With outstanding chemical, moisture, and radiation resistance, this film is engineered to perform in aggressive and high-humidity environments. The FEP coating delivers a stable non-stick, glossy surface, enhancing lifespan and ease of processing. Its impressive flexibility and mechanical strength ensure suitability for complex manufacturing and demanding operational conditions.

FAQs of FEP Polyamide Film:

Q: How does the FEP Polyamide Film enhance electrical insulation performance?

A: Thanks to the polyimide base and FEP coating, the film achieves high dielectric strength and thermal insulation, supporting expected breakdown voltages of 512 kV depending on thickness. This combination offers dependable protection for wires, transformers, motors, and electronic circuits in high-voltage and high-frequency applications.Q: What environments are suitable for installing FEP Polyamide Film?

A: This film thrives in both low and high temperature environments, withstanding continuous exposure from -200C up to +200C, and even tolerating short-term spikes to 260C. Its chemical and moisture resistance make it suitable for industrial, automotive, aerospace, and electronic manufacturing settings where reliability and safety are paramount.Q: Where can FEP Polyamide Film be used effectively?

A: It is commonly used in wire and cable insulation, transformer and motor wrapping, flexible printed circuits (FPC), high-temperature adhesive tapes, as well as coil, sensor, and heater insulation. Its adaptability to various voltages and frequencies makes it a preferred solution in aerospace, automotive, and electronics industries.Q: What is the recommended handling and installation process?

A: FEP Polyamide Film should be stored in a clean, dry environment to preserve its properties. During processing, controlled heat sealing or lamination is recommended to ensure uniform bonding. The films superior flexibility and mechanical strength facilitate easy slitting, cutting, and shaping to fit diverse design requirements.Q: What are the benefits of using FEP Polyamide Film in demanding applications?

A: Users gain long-term electrical insulation, high heat resistance (continuous up to 200C), chemical and moisture resilience, and non-stick surface characteristics. These attributes reduce performance failures, extend operational life, and ensure safety in critical systems, such as aerospace and automotive wiring and electronic components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese