- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Acrylic Fiberglass Sleeving

- Varnished Fiberglass Sleeve F Class

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Pure Aramid Paper

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

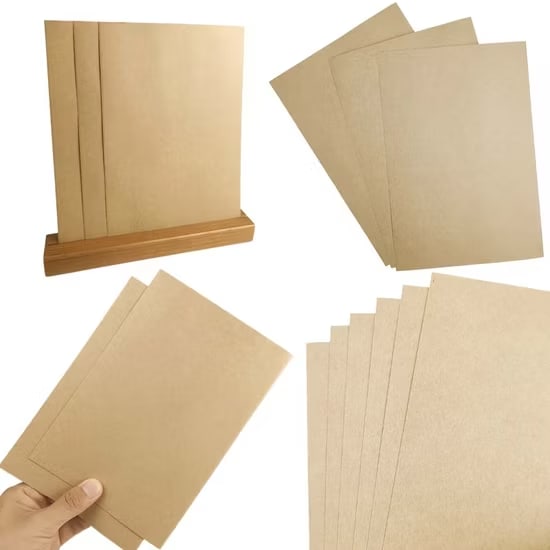

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

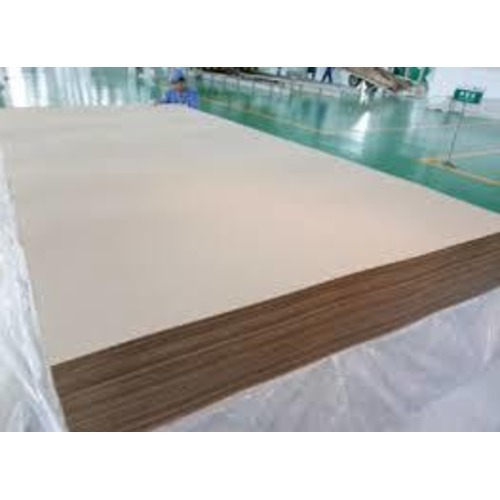

Insulation Pressboard

20.0 INR/Kilograms

Product Details:

- Feature Good Quality

- Product Type Insulating Press Board

- Warranty Yes

- Usage & Applications Industrial

- Color Cream

- Display Type Nil

- Features Good Quality

- Click to view more

X

Insulation Pressboard Price and Quantity

- 20.0 INR/Kilograms

- 1 Kilograms

Insulation Pressboard Specification

- Cream

- Nil

- Insulating Press Board

- Yes

- Good Quality

- Industrial

- Good Quality

Insulation Pressboard Trade Information

- Cash Advance (CA), Cheque, Cash in Advance (CID), Telegraphic Transfer (T/T)

- 20000 Kilograms Per Month

- 1 Days

- No

- Free samples are available

- Eastern Europe, Western Europe, Middle East, Africa, South America, Central America, North America, Asia, Australia

- All India

- CE & RoHS

Product Description

The electrical and power industries employ insulation pressboard, sometimes referred to as transformer pressboard or electrical pressboard, for structural purposes and insulation. It is frequently used in the development of reactors, high-voltage transformers, and other electrical machinery. High-quality cellulose fibres are meticulously processed and crushed to produce insulation pressboard, which is a dense, homogenous, and sturdy material with superior insulating qualities.

An Overview Of Insulated Pressboard Is Given Below:

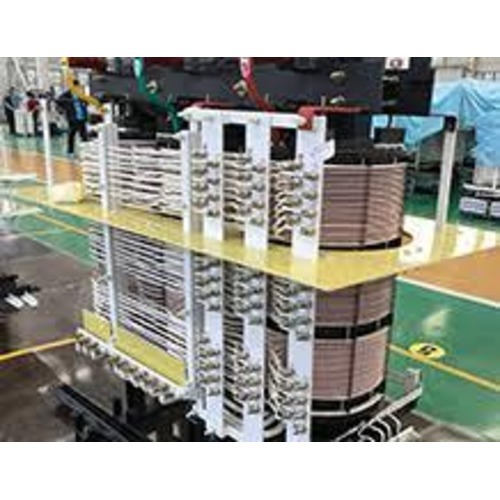

1. Electrical Insulation: One of insulation pressboards main applications is as an electrical insulator. It is suitable for applications where electrical insulation is necessary to prevent short circuits and ensure the safe functioning of high-voltage equipment because of its high dielectric strength and resistance to electric fields.

2. Mechanical Strength: Insulation pressboard is designed with great dimensional stability and mechanical strength in mind. It is capable of withstanding mechanical strain, pressure, and vibration, making it appropriate for supporting the transformers core and windings.

3. Heat Resistance: This substance has excellent thermal stability and is able to tolerate high temperatures without suffering appreciable degradation. It is frequently used in transformers and other electrical equipment that generates heat while in use.

4. Oil Impregnation: To further improve the electrical and thermal qualities of insulation pressboard, it can be impregnated with mineral oil or other insulating oils. Its performance as a dielectric is enhanced and its resistance to moisture is increased by oil impregnation.

5. Compatibility:Pressboard is able to act in concert with the insulating oils frequently used in transformers to enhance overall insulation and heat dissipation.

6. Applications: Power generating, transmission, and distribution systems all make use of insulation pressboard. In transformers, reactors, and other electrical equipment, it serves as a support for windings as well as a barrier and insulation between layers of conductors.

7. Types: Insulation pressboard comes in a variety of grades and types, each created for a particular use and range of voltage. Different voltage levels and mechanical requirements are met by different thicknesses and densities.

8. Environmental Concerns: Pressboard is frequently constructed from cellulose fibres that can be renewed, making it more environmentally benign than other synthetic materials. To achieve the best insulating qualities, however, chemical treatments could be used during manufacture.

9. Standards and Regulations: In order to guarantee the functionality and safety of electrical equipment, insulation pressboard must adhere to industry standards and regulations. These specifications specify terms like dielectric strength, moisture resistance, and other crucial properties.

Insulation PressboardSpecifications:

|

No |

Items |

Unit |

Standard Value |

||

|

|

>1.6 mm-3.0 mm |

>3.0 mm-6.0 mm |

|||

|

1 |

Thickness tolerance |

% |

+-7.5 |

+-5.0 |

+-5.0 |

|

2 |

Density of the surface |

g/cm3 |

1.0-1-2 |

1.1-1.25 |

1.15-1.30 |

|

4 |

Elongation strength |

Mpa |

>_100 |

>_105 |

>_110 |

|

Mpa |

>_75 |

>_80 |

>_85 |

||

|

5 |

Shrinkable rate |

% |

|

|

|

|

% |

|

|

|

||

|

% |

|

|

|

||

|

6 |

Moisture content |

% |

|

|

|

|

7 |

Ash content |

% |

|

|

|

|

8 |

Conduction of aqueous extract |

mS/m |

|

|

|

|

9 |

PH of aqueous extract |

6.0-9.0 |

|

|

|

|

10 |

Electrical strength in oil |

Kv/mm |

>_40 |

>_35 |

>_30 |

FAQ

1. How is insulation pressboard utilised in the electrical sector?

Ans - In the electrical industry, insulation pressboard is widely utilised in reactors and transformers, among other applications. It works as a top-notch insulating material that offers these products electrical insulation, structural support, and heat resistance.

2. How does insulation pressboard affect transformer performance?

Ans- In order to retain the winding geometry and provide electrical insulation between the layers of windings, insulation pressboard is an essential component of transformers. Additionally, it aids in the effective and safe performance of transformers by managing the heat that is produced during operation.

3. Are transformer oils compatible with insulation pressboard?

Ans - Yes, insulation pressboard and the insulating oils used in transformers are frequently compatible. Pressboard can be oil-impregnated to improve its moisture resistance and insulating capabilities. This impregnation procedure increases the dielectric performance and service life of the material.

4. Do several varieties of insulation pressboard exist?

Ans - Yes, there are several insulating pressboard types and grades created to satisfy various specifications and voltage classes. Different voltage levels and mechanical requirements are met by these differences in thickness, density, and composition, ensuring optimal performance in a variety of applications.

5. Which criteria govern the use of insulation pressboard?

Ans - To ensure the efficiency and safety of electrical equipment, industry norms and regulations govern the usage of insulation pressboard. These specifications outline the requirements that the material must fulfil in order to provide adequate insulation and consistent performance, including dielectric strength, moisture resistance, and other crucial qualities.

Versatile Industrial Applications

Insulation Pressboard finds extensive use in industrial settings, particularly for insulation in electrical machinery like transformers, motors, and switchgear. Its robust structure and range of thicknesses allow it to adapt to various requirements, making it a preferred choice for professionals seeking dependable insulating materials.

High Quality and Warranty Assurance

Crafted from premium kraft paper and delivered in cream color, this insulation pressboard stands out for its consistent quality and performance. The warranty provided with every purchase further solidifies its reliability, offering users assurance against material and manufacturing defects.

FAQs of Insulation Pressboard:

Q: How is Insulation Pressboard typically used in industrial applications?

A: Insulation Pressboard is primarily employed as an electrical insulating material in equipment such as transformers, switchgear, and other assemblies that require reliable dielectric strength to prevent electrical leakage and ensure operational safety.Q: What processes are involved in manufacturing Insulation Pressboard from kraft paper?

A: The manufacturing process involves pulping high-quality kraft paper, pressing it into sheets, and refining it to the desired thickness. The final product undergoes rigorous quality checks to maintain its good quality and insulation properties before distribution.Q: When should Insulation Pressboard be chosen over other insulation materials?

A: It should be selected when high dielectric strength, durability, and precision in thickness are needed, such as in transformer windings or environments subjected to electrical stress. Its standardized quality and range of thicknesses make it suitable for varied industrial insulation demands.Q: Where can Insulation Pressboard be sourced in India?

A: This pressboard is accessible from leading distributors, exporters, importers, manufacturers, suppliers, and traders across India, ensuring a wide network for procurement and support.Q: What are the benefits of using cream-colored, good quality Insulation Pressboard?

A: The cream color signifies purity in the kraft base, while the good quality ensures it maintains consistency in insulation performance, longevity under electrical load, and ease of installation in industrial devices.Q: How does the product warranty benefit the end-user?

A: The included warranty provides end-users with assurance against manufacturing or material defects, allowing for uninterrupted use and minimizing operational risks associated with insulation failure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese