- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Fire Resistant Sleeve

- Polyester Expandable Braided Sleeves

- Insulation Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Polyurethane Fiberglass Sleeve

- Fire Sleeves

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Laminated Fleece Paper

- Eurotherm Laminated Nomex Paper NPN

- Electrical Insulating Paper

- Laminated Aramid Paper

- Saturated Fleece Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Pure Aramid (Nomex) Paper

- Electrical Insulation Papers and Laminates

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

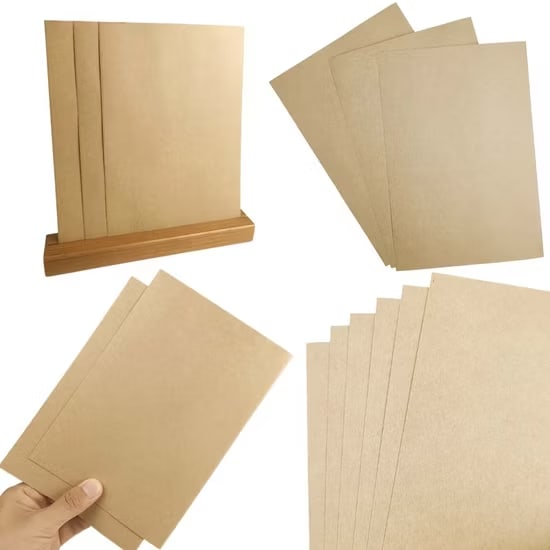

Insulation Pressboard

20.0 INR/Kilograms

Product Details:

- Material Wood Pulp

- Paper Type Craft Paper

- Coating Coated

- Thickness 8 to 50 Millimeter (mm)

- Color White

- Click to view more

X

Insulation Pressboard Price and Quantity

- 1 Kilograms

- 20.0 INR/Kilograms

Insulation Pressboard Specification

- Craft Paper

- Wood Pulp

- Coated

- White

- 8 to 50 Millimeter (mm)

Insulation Pressboard Trade Information

- 1000 Kilograms Per Month

- 3 Days

Product Description

Electrical Insulation Presspaper Oil Transformer Used Wood Pulp Kraft Paper Laminated Press Board Insulation Material Factory Price New Material

Insulation Pressboards are paper types that are used as electrical insulation in many applications due to pure cellulose having outstanding electrical properties. Cellulose is a good insulator and is also polar, having a dielectric constant significantly greater than one. Electrical paper products are classified by their thickness, with tissue considered papers less than 1.5 mils (0.0381 mm) thickness, and board considered more than 20 mils (0.508 mm) thickness.

Frequently Asked Questions:

1. What are insulation pressboards?

Ans: Insulation pressboards are specialized materials used in transformers, switchgear, and other electrical equipment for electrical insulation applications. They are used to offer electrical and thermal insulation and are frequently constructed from cellulose or wood fibers.

2. What are the key properties of insulation pressboards?

Ans: High dielectric strength, great thermal stability, and resistance to moisture and oil are all characteristics of insulation pressboards. They can tolerate high temperatures and have a considerable mechanical strength.

3. How are insulation pressboards manufactured?

Ans: Insulation pressboards are typically produced by compressing layers of cellulose or wood fibers under high pressure and heat. This process creates a dense and homogeneous material with excellent insulating properties.

4. What are the common applications of insulation pressboards?

Ans: Insulation pressboards are used in a wide range of electrical equipment, including power transformers, distribution transformers, bushings, circuit breakers, and insulating barriers. They provide electrical insulation and help manage heat generated during operation.

5. What are the different types of insulation pressboards available?

Ans: There are several types of insulation pressboards, including standard pressboard, creped pressboard, and diamond-dotted pressboard. Each type has unique characteristics and is chosen based on the specific requirements of the application.

Superior Electrical Insulation

Crafted from high-grade wood pulp and finished with a protective coating, our insulation pressboard provides exceptional dielectric strength. Its versatile thickness range guarantees optimum safety and efficiency for high-voltage and industrial electrical applications.

Reliable Craft Paper Construction

Engineered as coated craft paper, the insulation pressboard combines flexibility with formidable durability. The white color and smooth finish create a professional appearance for equipment, while delivering trusted operational integrity across diverse environments.

FAQs of Insulation Pressboard:

Q: How is the insulation pressboard manufactured?

A: The insulation pressboard is produced from quality wood pulp, which is processed into craft paper and then coated to enhance its electrical insulation properties. Thicknesses are precisely controlled during manufacturing to meet a range of industrial specifications, from 8 to 50 millimeters.Q: What is the main application of this pressboard?

A: This pressboard is primarily used in electrical equipment such as transformers and switchgear, where superior insulation is required to withstand high voltages and ensure operational safety.Q: When should I use insulation pressboard made from wood pulp?

A: Insulation pressboard made from wood pulp is best used when demanding electrical insulation, mechanical strength, and thickness flexibility are vital. It excels in scenarios involving heavy-duty electrical installations and repairs.Q: Where can I source this insulation pressboard in India?

A: You can obtain white insulation pressboard from manufacturers, suppliers, distributors, exporters, importers, and traders across India. We offer nationwide coverage and serve a variety of industrial sectors.Q: What is the process for installing this product in electrical systems?

A: Installation typically involves cutting the pressboard to size and fitting it within enclosures or around components requiring insulation. Its coated surface ensures easy handling and seamless integration into both new installations and maintenance tasks.Q: How does coated craft paper benefit electrical insulation?

A: The coating on the craft paper enhances surface stability, moisture resistance, and overall dielectric performance. This results in improved longevity and reliability, safeguarding electrical components from breakdown or short-circuits.Q: What are the benefits of using this insulation pressboard?

A: Benefits include excellent electrical insulation, high mechanical strength, customizable thicknesses, easy installation, and reliable performance in challenging industrial environments. The product meets strict quality standards and supports long-term equipment safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese