- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Insulation Sleeves

- Polyester Expandable Braided Sleeves

- Fire Resistant Sleeve

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Polyurethane Fiberglass Sleeve

- Fire Sleeves

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Pure Aramid Paper

- Eurotherm Laminated Nomex Paper NPN

- Laminated Fleece Paper

- Electrical Insulating Paper

- Saturated Fleece Paper

- Laminated Aramid Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Pure Aramid (Nomex) Paper

- Electrical Insulation Papers and Laminates

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

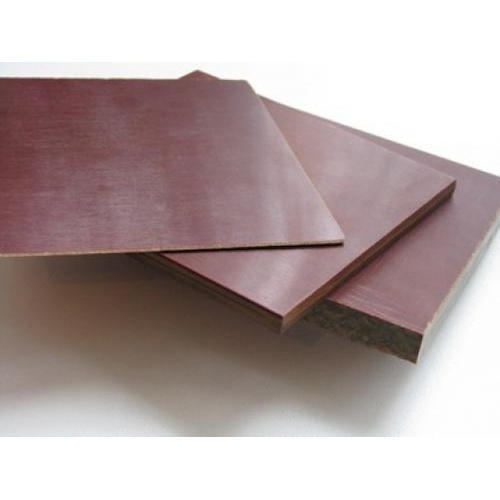

Hylam and Bakelite Sheet

80.0 INR/Kilograms

Product Details:

- Surface Treatment Smooth

- Size Standard

- Material Hylam and Bakelite

- Thickness 0.5 Millimeter (mm)

- Color Brown

- Click to view more

X

Hylam and Bakelite Sheet Price and Quantity

- 1 Kilograms

- 80.0 INR/Kilograms

Hylam and Bakelite Sheet Specification

- Hylam and Bakelite

- Smooth

- 0.5 Millimeter (mm)

- Standard

- Brown

Hylam and Bakelite Sheet Trade Information

- 3 Days

- Asia, Australia, North America, South America, Central America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Industrial laminates like Hylam sheet and Bakelite sheet are both employed in a variety of applications, especially in the mechanical and electrical sectors. They are renowned for their mechanical toughness, durability, and electrical insulation. Lets examine each in more detail:

Phenolic Laminated Sheet is a form of industrial laminate that goes by the trade name Hylam Sheet. Layers of paper or fabric are impregnated with phenolic resin and then heated and compressed to cure them. For applications requiring electrical insulation, mechanical strength, and chemical resistance, hylam sheets are frequently employed.

Phenolic resin, also recognised as the first synthetic plastic substance, is also known by the trade name Bakelite. Hylam sheets and bakelite sheets both have layers of paper or cloth that have been treated with phenolic resin and then dried. The mechanical toughness and electrical insulating qualities of bakelite sheets make them valuable.

Brown Hylam Sheet Bakelite Sheet marketed by us comes in a variety of thicknesses and grades. Because of its dimensional precision, mechanical strength, heat resistance, and low water absorption, our good is constructed from premium quality raw materials that are in high demand. This sheet is a double-sided high-pressure laminate. Brown Hylam Sheet Bakelite Sheet is tested by experts to verify that the design, glossiness, and surface finish are appropriate. Liquor, agriculture, food, and a variety of other industries use our product.

Key Points:

- This sheet can be used alone to create whole products to create a laminate or surface coating.

- Used as a substitute for hard rubber; for insulating electrical apparatus

- Great shock-absorption abilities

- Electrical characteristics superior

- Excellent machinability

- This is very effective and safe to use

- Long-lasting service life

Hylam and Bakelite sheets have the following qualities in common:

1. Electrical Insulation: Because these materials are effective electrical insulators, they can be used in situations where it is important to avoid electrical conduction, such as insulating parts of electrical equipment.

2. Hylam and Bakelite sheets provide good dimensional stability and mechanical strength. They are useful for structural components since they can endure pressure and mechanical stress.

3. Heat Resistance: For applications requiring heat-generating components, it is crucial that the materials used are heat-resistant and able to withstand high temperatures without significantly degrading.

4. Hylam and Bakelite sheets are resistant to a wide range of chemicals and solvents, which adds to their longevity and suitability for industrial settings.

5. Both materials are easily machined, drilled, and cut into a variety of shapes, making it possible to create unique components and parts.

6. Hylam and Bakelite sheets are used in a variety of mechanical and industrial applications, including electrical insulation, switchgear parts, panels, gaskets, bearings, and gears.

FAQ

1. How are Bakelite and Hylam sheets made?

Ans - An industrial laminate comprised of layers of paper or fabric impregnated with phenolic resin is what Hylam Sheets and Bakelite Sheets are. The materials produced by curing these layers under pressure and heat are long-lasting, heat-resistant, and electrically insulating.

2. What are the primary uses for Bakelite and Hylam sheets?

Ans - Both Bakelite and Hylam sheets are used in a variety of industries. They are frequently used in electrical equipment, panels, and switchgear components as electrical insulation. They are also used in mechanical applications such structural parts, bearings, gears, and gaskets.

3. Are Bakelite and Hylam sheets resistant to heat?

Ans - Both Bakelite and Hylam sheets can withstand heat, so the answer is yes. As a result of their ability to tolerate high temperatures without significantly degrading, they are appropriate for applications involving heat-generating elements and surroundings.

4. What distinguishes "Hylam" from "Bakelite"?

Ans - In contrast, "Bakelite" originally refers to the first synthetic plastic substance created by Leo Baekeland, whereas "Hylam" is a specific brand name for phenolic laminated sheets. In the course of time, the term "Bakelite" grew to be synonymous with phenolic resin and is occasionally used in a general sense to designate related materials, such as phenolic laminated sheets like Hylam.

5. Can Hylam and Bakelite sheets be modified for particular uses?

Ans - In order to fit certain applications, both types of sheets can be simply machined, drilled, and cut into different shapes. Due to its versatility, unique parts and components can be made to meet the needs of various projects and sectors.

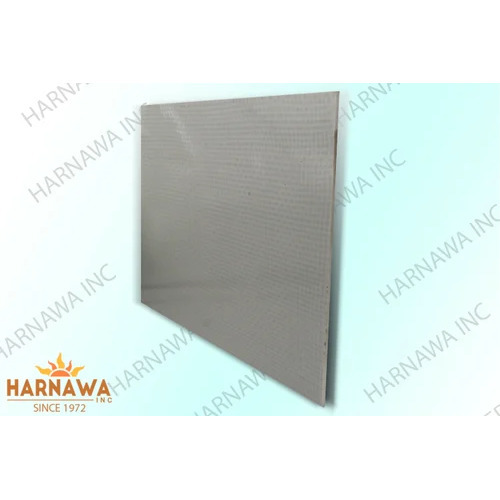

Exceptional Surface Finish and Durability

These Hylam and Bakelite Sheets feature a smooth surface treatment ensuring minimized friction and easy maintenance. Renowned for their toughness, they are resistant to impact, chemicals, and heat, making them a preferred choice for demanding industrial environments.

Versatile Applications Across Industries

Ideal for insulation, electrical panels, gaskets, and machine parts, the 0.5 mm thick Hylam and Bakelite Sheets find widespread application in electrical, automotive, and manufacturing sectors. Their reliable properties ensure consistent performance under various operational conditions.

FAQs of Hylam and Bakelite Sheet:

Q: How are Hylam and Bakelite Sheets manufactured?

A: These sheets are produced through a lamination process, where layers of phenolic resin-impregnated paper or fabric are bonded together using heat and pressure. This process ensures a homogeneous structure with excellent mechanical strength and electrical insulation properties.Q: What are the primary uses of Hylam and Bakelite Sheets?

A: Hylam and Bakelite Sheets are primarily utilized for electrical insulation, making switchboards, panel boards, gaskets, and mechanical components. Their robust and heat-resistant nature also makes them suitable for automotive and industrial applications.Q: When should I choose a 0.5 mm thickness for these sheets?

A: A 0.5 mm thickness is ideal when you require lightweight insulation or components with fine dimensional tolerances. It is especially suitable for applications where flexibility and minimal space are crucial, such as electronic devices and compact machinery.Q: Where are your Hylam and Bakelite Sheets distributed?

A: We supply our sheets throughout India and also cater to international clients as an exporter and importer. Our established distribution network ensures timely delivery and consistent product availability in major industrial hubs.Q: What is the process for sourcing sheets from your company?

A: Customers can place orders directly through our sales team or website. We offer tailored solutions based on your specifications and ensure a streamlined supply process from order confirmation to timely shipment.Q: How do the sheets benefit electrical and industrial applications?

A: Due to their high dielectric strength, mechanical robustness, and resistance to heat and chemicals, these sheets provide reliable insulation, prolong equipment life, and reduce maintenance requirements in critical environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese